Construction waste refers to the waste generated during the construction, renovation, demolition, or deconstruction of buildings, infrastructure, and other structures. This waste may include debris, rubble, concrete, asphalt, wood, plastics, metals, and other materials that are no longer needed or are removed during the construction process.

24 Online Service

Construction waste can have significant environmental impacts if not managed properly. It can contribute to air and water pollution, land degradation, and greenhouse gas emissions. To address these concerns, many countries and organizations have implemented regulations and best practices for the proper management of construction waste.

Some common methods of managing construction waste include recycling, reusing, and reducing the amount of waste generated in the first place. Recycling and reusing materials such as concrete, wood, and metal can reduce the amount of waste that ends up in landfills and reduce the need for new raw materials. Additionally, designing buildings with sustainable and durable materials and minimizing waste during the construction process can also help to reduce the amount of construction waste generated.

Construction waste is a major contributor to environmental pollution and landfills. However, recycling construction waste can help to mitigate these problems.

Onsite separation and recycling involve separating the waste materials at the construction site and processing them for reuse on the same site. This method is also known as in situ recycling. This method of recycling is most effective for large construction projects, such as the construction of highways, where the amount of waste generated is significant.

The waste materials are separated into various categories, such as concrete, wood, metal, and plastics. Once the waste materials are separated, they are processed using specialized equipment to turn them into reusable materials. For example, concrete waste can be crushed and used as a base for new construction projects, while wood waste can be turned into wood chips or mulch.

Construction and Demolition (C&D) recycling involves the processing of waste materials from construction sites at specialized recycling facilities. This method is suitable for smaller construction projects where onsite recycling is not possible. The waste materials are transported to the recycling facility where they are sorted and processed for reuse.

C&D recycling facilities have specialized equipment for processing the waste materials. For example, concrete waste can be crushed and used as aggregate for new construction projects, while metal waste can be melted down and reused in new construction projects. This method of recycling is cost-effective and can help to reduce the amount of waste that ends up in landfills.

Salvaging and reusing involves the recovery of materials from buildings that are being demolished. This method is most effective for older buildings that have historical or architectural value. Salvaging and reusing materials can help to reduce the environmental impact of construction by reducing the amount of waste that ends up in landfills.

The materials that are salvaged can be used in new construction projects or sold to other construction companies. For example, salvaged wood can be used to make furniture or flooring, while salvaged metal can be melted down and used in new construction projects. This method of recycling is cost-effective and can help to reduce the environmental impact of construction.

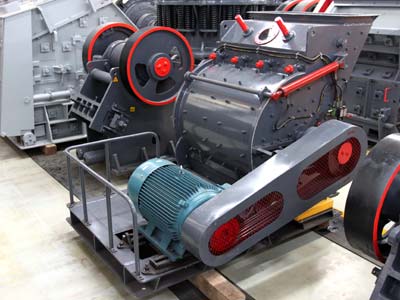

One of the key steps in managing construction waste is crushing. Crushing is the process of reducing the size of materials to make them easier to handle and transport, and to make them suitable for reuse or recycling. There are several types of crushers that can be used for crushing construction waste, including jaw crushers, impact crushers, cone crushers, and hammer crushers. Each type has its own advantages and disadvantages, and the choice of crusher depends on the type and amount of waste, as well as the desired end product.

Jaw crushers are commonly used for primary crushing of large chunks of materials. They work by compressing the material between two plates, with one stationary and one moving. This process creates a “V”-shaped opening at the top of the crusher, which is used to feed the material. Jaw crushers are ideal for processing hard and abrasive materials, such as concrete and bricks, and can produce a range of particle sizes.

Impact crushers are used to crush materials by using a high-speed rotor with hammers that strike the material. This type of crusher is ideal for processing softer materials, such as asphalt and gypsum, and can produce a range of particle sizes. Impact crushers are also useful for producing a more cubical shape for concrete and asphalt aggregates.

Cone crushers work by using a rotating mantle within a concave bowl to crush materials. This process is ideal for processing harder materials, such as granite and basalt, and can produce a range of particle sizes. Cone crushers are also useful for producing a more cubical shape for concrete and asphalt aggregates.

Hammer crushers use a series of rotating hammers to crush materials. They are useful for processing softer materials, such as coal and limestone, and can produce a range of particle sizes. Hammer crushers are also useful for producing a more uniform particle size distribution for concrete and asphalt aggregates.

Once the construction waste has been crushed, the next step is to separate the different materials for recycling or reuse. This can be done through a variety of methods, such as magnetic separation, Screening, and air classification. Magnetic separation is used to separate metals from non-metals, such as iron from concrete. Screening is used to separate materials by size, such as wood chips from concrete rubble. Air classification is used to separate materials by density, such as plastics from concrete.

Recycling construction waste has several benefits. It reduces the amount of waste that ends up in landfills, which can lead to environmental problems such as groundwater contamination and greenhouse gas emissions. Recycling also conserves natural resources, such as wood and aggregates, and reduces the need for new materials to be mined or harvested. Additionally, recycling construction waste can create new jobs and stimulate local economies.

In addition to recycling, there are other ways to reuse construction waste. For example, concrete rubble can be used as a base for new roads or as a construction material for new buildings. Wood waste can be used for biomass energy production or as a source of mulch for landscaping. Metals can be sold to scrap yards for recycling.

One of the most effective ways of dealing with construction waste is through recycling. Recycling involves the collection and processing of waste materials so that they can be used again. This not only helps to reduce the amount of waste going to landfill but it also conserves natural resources and reduces greenhouse gas emissions.

Construction waste recycling has been around for several decades and it is a process that involves crushing and screening of waste materials. The waste is then sorted into different categories based on its composition and the materials are recycled accordingly. Some of the common materials that are recycled from construction waste include concrete, bricks, wood, metals, plastics, and glass.

The crushing of construction waste is an important process in the recycling process. This involves the use of heavy-duty machinery to crush the waste materials into smaller pieces. The crushed material is then sorted and processed so that it can be used again.

There are several benefits of construction waste crushing and recycling. One of the main benefits is that it helps to reduce the amount of waste going to landfill. Landfill sites are filling up at an alarming rate and it is therefore important to find ways of reducing the amount of waste going to these sites. By recycling construction waste, we can divert a significant amount of waste from landfill sites and conserve precious landfill space.

Another benefit of construction waste recycling is that it conserves natural resources. Many of the materials used in construction, such as concrete, are non-renewable resources. By recycling these materials, we can reduce our dependence on these resources and conserve them for future generations.

Recycling construction waste also helps to reduce greenhouse gas emissions. The production of new materials requires a significant amount of energy and this energy consumption contributes to greenhouse gas emissions. By recycling construction waste, we can reduce the amount of energy required to produce new materials and this in turn reduces greenhouse gas emissions.

In addition to these benefits, construction waste recycling also has economic benefits. Recycling creates jobs and generates revenue for businesses. It also reduces the cost of waste disposal and this can result in cost savings for construction companies.

Construction waste recycling equipment is designed to sort, process, and recycle construction waste materials. There are various types of equipment available that can handle different types of waste materials. These include crushers, shredders, and sorters.

Crushers are machines that break down large pieces of construction waste into smaller, more manageable pieces. These machines come in various sizes and can be used to crush different types of waste materials. For example, a jaw crusher is commonly used to crush concrete and brick, while a cone crusher is used for rock and ore. Crushers can help reduce the size of waste materials, making it easier to transport and recycle them.

Shredders are machines that shred waste materials into smaller pieces. They are particularly useful for processing wood and other organic materials. The shredded material can be used as biomass for energy production or as mulch for landscaping. Shredders are also useful for processing other types of waste materials, such as plastics and cardboard.

Sorters are machines that separate different types of waste materials. For example, a magnetic separator can be used to separate metal from concrete and other materials. This makes it easier to recycle the metal and reduces the amount of waste that ends up in landfills. Optical sorters are also available that can separate different types of plastics based on their color and density.

Another type of construction waste recycling equipment is the mobile recycling plant. These plants are designed to be transported to construction sites, allowing waste materials to be processed on-site. This reduces the need for transportation and helps to reduce the amount of waste that ends up in landfills.

Advancements in technology have led to the development of mobile crushers for construction waste. These crushers are capable of processing a wide range of construction waste materials into reusable products, which can help reduce waste and contribute to sustainable development.

Mobile crushers are portable machines that can be easily transported to construction sites, making it easier to process waste materials on-site. This reduces the need for transportation of waste materials to landfills, which is both time-consuming and costly.

The use of mobile crushers for construction waste has several benefits. Firstly, it helps to reduce the amount of waste that is sent to landfills. This, in turn, reduces the environmental impact of waste disposal and contributes to sustainable development. Additionally, the use of mobile crushers can help to save money, as it eliminates the need for transportation of waste materials to landfills.

Another benefit of mobile crushers for construction waste is that they can process a wide range of materials. This includes concrete, bricks, asphalt, and other materials that are often difficult to process using traditional methods. This versatility makes mobile crushers an ideal solution for construction companies that need to process a variety of waste materials.

Mobile crushers for construction waste also offer a high level of automation, making them easier to operate and maintain. This reduces the need for manual labor, which can save time and money. Additionally, the automation of mobile crushers helps to ensure that the process is consistent, resulting in high-quality products that can be reused in construction projects.

The use of mobile crushers for construction waste is also beneficial for the environment. By reducing the amount of waste that is sent to landfills, mobile crushers help to reduce the amount of greenhouse gases that are released into the atmosphere. This is because when waste is sent to landfills, it decomposes and releases methane, which is a potent greenhouse gas. By processing waste materials on-site, mobile crushers help to prevent this from happening.

Mobile crushers for construction waste are also beneficial for the construction industry. This is because they allow construction companies to reuse waste materials in new construction projects, reducing the need for materials. This, in turn, helps to conserve natural resources and reduces the environmental impact of construction projects.

Our Projects

Copyright © ZENITH, All Right Reserved.