Choosing between wheeled and tracked mobile crushers depends on various factors such as mobility, versatility, speed, efficiency, and maintenance costs. Wheeled crushers provide excellent maneuverability and are well-suited for projects that require frequent relocation or work in urban environments.

24 Online Service

Tracked crushers have revolutionized the quarrying and mining industries by providing efficient and mobile solutions for crushing and screening operations. These machines are equipped with advanced technologies and robust components that enable them to handle various types of materials with ease.

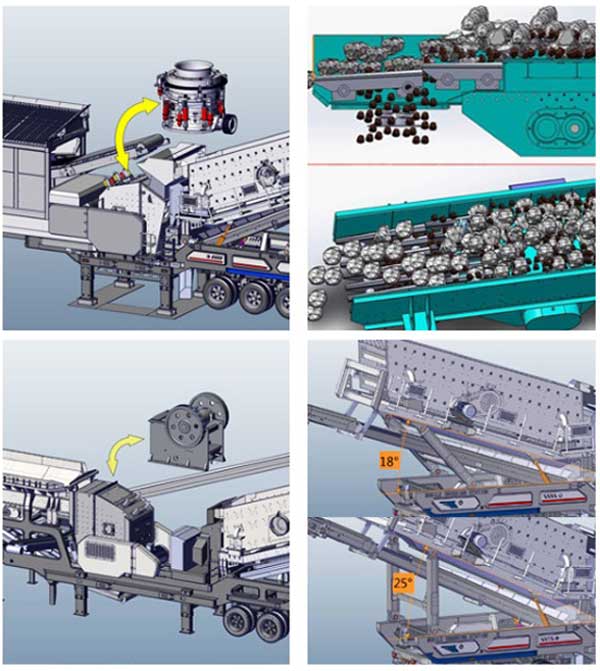

One of the fundamental components of a tracked crusher is its undercarriage system. The undercarriage, consisting of tracks, frames, and crawler assemblies, plays a vital role in supporting and maneuvering the machine. Typically constructed with heavy-duty materials, such as steel or reinforced rubber, the tracks provide excellent traction and stability on diverse terrains, including rough and uneven surfaces.

The undercarriage is designed to distribute the machine’s weight evenly, reducing ground pressure and preventing excessive wear and tear. Moreover, modern tracked crushers often feature advanced track systems with self-adjusting tensioners, which help maintain optimal track tension, extend track life, and minimize maintenance requirements.

Tracked crushers are powered by robust engines, typically diesel or hybrid-electric, which generate the energy required for crushing operations. These engines are selected based on factors such as power output, fuel efficiency, and emission regulations. Diesel engines are commonly used due to their high torque capabilities and reliability in demanding environments.

The power generated by the engine is utilized by the hydraulic system, which operates various functions of the crusher. Hydraulic cylinders are employed to control the opening and closing of the crusher chamber, ensuring precise and efficient crushing. Additionally, hydraulic systems enable the adjustment of crusher settings to achieve different product sizes, enhancing flexibility in the production process.

The crushing chamber is where the actual crushing takes place and is a critical component of a tracked crusher. It is typically lined with replaceable manganese steel liners that protect the chamber walls from excessive wear caused by the crushing process. The shape and design of the chamber can significantly impact the performance and efficiency of the crusher.

Advanced tracked crushers often feature variable chamber configurations, allowing operators to optimize the crusher for specific applications. These configurations enable the adjustment of the chamber’s eccentric throw and cavity profiles, resulting in improved crushing performance and increased product quality.

Efficient feeding and conveying systems are essential for the smooth operation of a tracked crusher. Vibrating grizzly feeders or hydraulic feed hoppers are commonly employed to regulate the flow of material into the crusher. These systems prevent overloading, ensure consistent material feed, and protect the crusher from potential damages.

Once the material is crushed, conveyors are used to transport the processed material away from the crusher for further processing or stockpiling. Conveyors vary in length and capacity, and they play a vital role in optimizing production rates and reducing the need for manual handling.

Modern tracked crushers are equipped with advanced control and monitoring systems that enhance efficiency, safety, and operational control. These systems often include human-machine interface (HMI) displays, which provide real-time information about the machine’s status, settings, and performance metrics.

Additionally, control systems can automate various processes, such as start-up/shutdown sequences, crusher optimization, and remote monitoring. This automation improves overall operational efficiency, reduces the risk of human error, and enables operators to focus on other crucial tasks.

Safety is of paramount importance in any crushing operation, and tracked crushers are equipped with several safety features to protect operators and maintenance personnel. These features may include emergency stops, safety interlocks, access platforms, and guarding.

In addition to physical safety features, crushers often incorporate advanced technologies like proximity sensors, cameras, and alarms to enhance safety awareness and prevent accidents. These technologies provide real-time feedback to operators and help mitigate potential hazards.

The mining and construction industries rely heavily on efficient and versatile equipment to extract and process raw materials. One such vital piece of machinery is the wheeled mobile crusher. These innovative machines are designed to crush and screen various types of materials on-site, providing a flexible and cost-effective solution for industries worldwide.

The chassis serves as the foundation of a wheeled mobile crusher. It is typically made of heavy-duty steel and designed to withstand the rigors of demanding operating conditions. The chassis provides stability and structural integrity, ensuring safe and efficient movement on different terrains. Additionally, the mobility feature enables the crusher to be easily transported between job sites, reducing downtime and increasing operational flexibility.

At the heart of every wheeled mobile crusher is the crushing unit, responsible for processing the raw materials. The primary component of the crushing unit is the crusher chamber, where the material undergoes compression and fragmentation. Different types of crushers, such as jaw crushers, impact crushers, and cone crushers, may be employed based on the specific application and material characteristics. The crushing unit is equipped with wear-resistant liners to prolong its lifespan and ensure efficient crushing.

Wheeled mobile crushers often incorporate a screening and grading system to separate and classify different-sized materials. This system consists of a vibrating screen or deck, which mechanically sorts the crushed materials into various fractions. By separating materials of different sizes, the screening and grading system ensures a consistent product quality and enables efficient utilization of the crushed material.

Mobile crushers require a reliable and efficient power source to operate effectively. Diesel engines are commonly used to power wheeled mobile crushers due to their high torque, durability, and portability. Advanced engine management systems ensure optimal fuel efficiency and reduce emissions, complying with environmental regulations. Some crushers may also incorporate hybrid or electric power systems to further enhance energy efficiency and minimize the carbon footprint.

Conveyor systems play a crucial role in the overall efficiency of wheeled mobile crushers. These systems transport the crushed materials from the crusher chamber to the designated storage or processing areas. They consist of a series of belts or chains, along with pulleys and idlers, that facilitate the smooth and controlled transfer of materials. Conveyor systems can be adjustable in length and height to adapt to different operating conditions and facilitate efficient stockpiling or loading onto trucks for transportation.

To enhance safety and operational efficiency, many wheeled mobile crushers are equipped with remote control capabilities. Remote control systems enable operators to control the crusher’s functions from a safe distance, minimizing the risk of accidents and improving productivity. Additionally, telematics technology allows for real-time monitoring of crucial parameters such as fuel consumption, machine health, and maintenance schedules, enabling proactive maintenance planning and optimization of operational performance.

Crushing and screening operations can generate significant amounts of dust, posing health risks for workers and negatively impacting the environment. To address this issue, modern wheeled mobile crushers often incorporate dust suppression systems. These systems use water or chemical agents to suppress dust emissions, creating a safer and cleaner working environment.

Mobile crushers have emerged as a groundbreaking solution, enabling industries such as mining, construction, and recycling to extract and process materials on-site. These portable machines offer a wide range of capabilities, adapting to various applications and materials.

Among the most commonly used mobile crushers are jaw crushers. These robust machines feature a stationary jaw and a movable jaw, allowing them to exert pressure and crush materials with ease. Jaw crushers are renowned for their high production capacity and reliability, making them ideal for primary crushing tasks. They are capable of processing a wide variety of materials, including hard rocks, ores, and concrete.

Mobile impact crushers are designed to deliver exceptional performance in secondary and tertiary crushing operations. These crushers employ the principle of impact crushing, where the feed material is struck by rapidly rotating hammers and shattered upon impact. Impact crushers are versatile and can handle a wide range of materials, including asphalt, limestone, and demolition debris. Their ability to produce precisely shaped end products makes them valuable for applications such as road construction and aggregate production.

Cone crushers are widely utilized in the mobile crushing industry due to their efficiency and versatility. These crushers operate by compressing the feed material between a mantle and a concave, producing finer and more uniform-sized aggregates. Cone crushers are particularly suitable for crushing hard and abrasive materials such as granite and basalt. Their ability to adjust the crusher settings enables operators to optimize production and achieve desired product specifications.

The LD series mobile crusher is a versatile and efficient machine that has become increasingly popular in recent years. Its mobility, efficiency, and safety features make it well-suited for a variety of applications, including construction and demolition waste recycling, quarrying and mining, and road and bridge construction. If you are looking for a mobile crusher that can provide flexibility and efficiency, the LD series mobile crusher is definitely worth considering.

In the ever-evolving world of construction and mining industries, the demand for efficient and versatile crushing equipment continues to grow. Two popular options available in the market today are wheeled mobile crushers and tracked mobile crushers. While both solutions offer their unique advantages, it is crucial to understand their differences to make an informed decision for your specific crushing requirements.

Wheeled mobile crushers are designed to be transported easily from one job site to another, utilizing a road-worthy chassis. These crushers are equipped with wheels, allowing them to be towed or driven to the desired location. This mobility aspect makes wheeled crushers an excellent choice for operations that require frequent relocation.

One of the key benefits of wheeled mobile crushers is their ability to offer flexible setups. They can be customized to include various crushing and screening units, such as jaw crushers, impact crushers, or cone crushers, depending on the specific application. This versatility allows operators to adapt the equipment to different types of materials and production requirements, making wheeled crushers suitable for a wide range of tasks.

Tracked mobile crushers, on the other hand, are built with a robust crawler system that provides excellent maneuverability and stability, even on challenging terrains. These crushers are self-propelled and can move independently, eliminating the need for additional transport equipment. The tracks enable tracked mobile crushers to traverse rough and uneven surfaces, making them ideal for operations in remote or rugged locations.

The primary advantage of tracked mobile crushers lies in their enhanced mobility and stability, which allows them to tackle various terrains and work effectively in different climates. They are particularly well-suited for large-scale projects and applications that demand continuous on-site crushing, such as mining and quarrying operations.

When deciding between wheeled and tracked mobile crushers, several factors should be taken into account:

Selecting the appropriate mobile crusher for your crushing operations is crucial for maximizing productivity, efficiency, and profitability. Wheeled and tracked mobile crushers each have their unique strengths, making them suitable for different applications.

Wheeled mobile crushers offer excellent mobility, flexibility, and ease of transportation, making them a viable choice for operations that require frequent relocation. On the other hand, tracked mobile crushers provide superior maneuverability, stability, and performance on rough terrains, making them well-suited for demanding projects and remote locations.

Ultimately, the decision between wheeled and tracked mobile crushers depends on your specific requirements, such as mobility needs, production capacity, operating costs, and environmental considerations. By carefully evaluating these

Our Projects

Copyright © ZENITH, All Right Reserved.