Vertical Roller Mills (VRMs) have emerged as game-changers in the cement industry for clinker grinding. Their ability to enhance efficiency, lower energy consumption, and reduce environmental impact has driven their widespread adoption across the globe.

24 Online Service

Cement is one of the most essential construction materials, serving as the binding agent in concrete, mortar, and other building applications. The cement manufacturing process is a complex and energy-intensive journey, involving several stages. Among these stages, cement clinker grinding plays a pivotal role in determining the quality and production costs of cement.

The cement manufacturing process begins with the extraction and preparation of raw materials. The primary ingredients include limestone, clay, silica, iron ore, and alumina, which are obtained from quarries and mines. These raw materials are then crushed into smaller pieces to facilitate the subsequent stages.

The next step involves blending and homogenizing the crushed materials to achieve a consistent mixture. This homogenized raw mix is then heated in a rotary kiln at extremely high temperatures, typically around 1450 degrees Celsius. Inside the kiln, a series of complex chemical reactions take place, leading to the formation of clinker.

Cement clinker is a crucial intermediate product in cement manufacturing and serves as the main building block in the production of cement. It is a nodular material produced during the sintering process in the kiln. The clinker is composed mainly of calcium silicates, aluminates, ferrites, and other minor compounds. Its composition significantly influences the final cement properties, including strength, setting time, and durability.

After exiting the kiln, the hot clinker is cooled and further processed to optimize its reactivity and grindability. This post-kiln processing involves clinker grinding, a critical stage that impacts cement quality and production costs significantly.

The fineness of cement particles is a key factor influencing the strength and performance of the final product. Efficient clinker grinding helps to achieve the desired fineness, enabling better particle packing and hydration rates. A finely ground clinker results in a larger surface area, facilitating more extensive chemical reactions and ultimately enhancing the strength and durability of the cement.

Clinker grinding determines the cement’s setting and hardening properties. When clinker particles are adequately ground, they hydrate more effectively during the mixing process with water. Proper hydration is crucial for the development of a strong and dense cement matrix, reducing the risk of cracking and improving the long-term performance of concrete structures.

The energy-intensive nature of cement production, particularly during clinker grinding, leads to significant greenhouse gas emissions, primarily CO2. Efficient grinding techniques, such as using high-pressure roller mills or advanced separator systems, can help reduce energy consumption, leading to a lower carbon footprint and environmental impact.

Clinker grinding constitutes a substantial portion of cement production costs. Efficient grinding processes result in higher production rates and reduced energy consumption, leading to cost savings. Moreover, finely ground clinker may allow the incorporation of supplementary cementitious materials (SCMs) like fly ash or slag, which can further enhance cement properties while reducing raw material costs.

Over the years, advancements in technology and process optimization have revolutionized the cement industry. Some key innovations in clinker grinding include:

VRMs have become increasingly popular in recent years due to their ability to grind materials with higher efficiency and lower energy consumption compared to traditional ball mills. They offer greater flexibility and control over particle size distribution, ensuring optimal cement performance.

HRPs are used as pre-grinding equipment before the ball mill, significantly reducing the energy required for particle size reduction in the subsequent grinding stage.

Incorporating advanced separator systems, such as high-efficiency classifiers and air separators, improves the overall grinding efficiency by ensuring the proper separation of fine and coarse particles.

The cement industry has been a key player in the global construction sector for centuries, providing the essential binding material for buildings, infrastructure, and various structures. Cement clinker, the primary component of cement, is produced through the grinding of raw materials like limestone, clay, and other additives. Traditional cement grinding processes involved ball mills, but in recent years, the development and widespread adoption of Vertical Roller Mills (VRMs) have revolutionized the cement clinker grinding process, bringing about significant improvements in efficiency, energy consumption, and environmental impact.

The widespread use of VRMs in the cement industry for clinker grinding can be attributed to the numerous success stories and proven benefits observed in various cement plants worldwide. As the demand for cement continues to rise, manufacturers are keen on adopting more efficient and sustainable technologies like VRMs to stay competitive and meet global environmental regulations.

VRMs enable cement plants to enhance their production capacities without substantial investments in new equipment or infrastructure. This advantage is particularly crucial for rapidly developing economies experiencing a surge in construction projects and infrastructure development.

Leading cement producers around the world have recognized the transformative potential of VRMs and incorporated them into their grinding operations. These companies have documented significant improvements in their productivity, energy efficiency, and environmental performance.

Numerous case studies demonstrate the success of VRMs in cement clinker grinding. Many cement manufacturers have reported substantial reductions in energy consumption (up to 30%) and increased cement production capacities (up to 50%) after implementing VRM technology.

The adoption of VRMs in the cement industry has spurred continuous technological advancements. Manufacturers are continually refining VRM designs to achieve even greater efficiency, durability, and product quality.

Vertical Roller Mills (VRMs) have emerged as a revolutionary technology in the field of industrial grinding. These sophisticated machines are widely used in the cement, coal, and minerals processing industries, enabling more efficient and cost-effective material grinding, bed compression, and separation processes.

The primary function of a vertical roller mill is to grind materials into extremely fine particles. This process is vital in various industries, as it facilitates the extraction of valuable minerals, reduces the size of coal particles for combustion, and produces finely ground cement for construction.

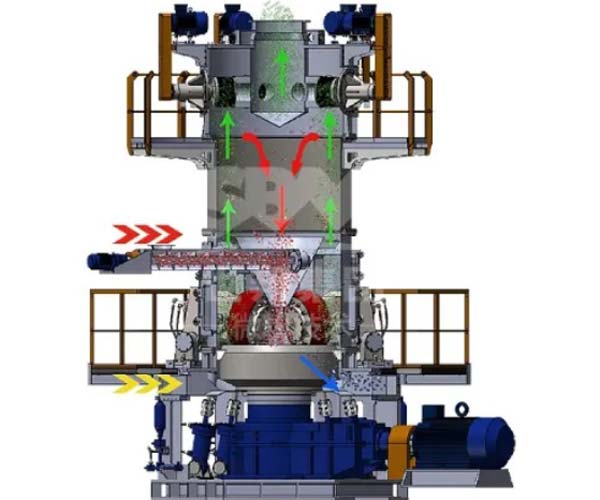

The heart of the VRM lies in its grinding table and rollers. The grinding table is a rotating component that supports the material to be ground. It is mounted on a gearbox-driven spindle, which imparts the required rotational force. Positioned around the circumference of the grinding table are the grinding rollers. These rollers exert pressure on the material, causing it to be crushed and ground against the table surface.

VRMs use hydraulic or pneumatic systems to apply pressure on the grinding rollers. The grinding pressure can be adjusted to control the fineness of the final product. The material to be ground is fed into the mill through a central chute or through side feeders. As the material passes between the grinding rollers and the table, it is subjected to both compression and shearing forces, resulting in the reduction of particle size.

Before the material is fed into the VRM, it is often pre-dried to reduce moisture content. Inside the mill, hot gases are typically used to facilitate drying and prevent clogging. The combination of grinding and drying in a single unit makes VRMs more energy-efficient compared to traditional ball mills, where separate drying equipment is required.

Another critical aspect of how VRMs work is the concept of bed compression. This principle enhances the grinding efficiency and reduces energy consumption while ensuring a stable and consistent operation.

During the grinding process, a thick and stable grinding bed is formed between the grinding table and the rollers. The material particles are embedded in the bed and subjected to high pressure, ensuring effective grinding.

Bed compression leads to several advantages over traditional grinding methods. Firstly, it allows for a more efficient use of energy, as the majority of the grinding action occurs in the bed rather than through direct impact. This results in lower energy consumption per ton of ground material. Secondly, the stable and uniform grinding bed ensures a more stable mill operation, reducing the risk of vibrations and fluctuations that could impact product quality and mill performance.

After the grinding process, the fine particles need to be separated from the coarser ones to obtain the desired product. VRMs employ efficient separation mechanisms to achieve this objective.

Vertical roller mills use integrated classifiers to control the particle size distribution of the ground material. The material is carried by the airflow from the grinding area to the classifier, where it is separated into fine and coarse particles. The fine particles are carried upward by the airflow and collected in a cyclone or bag filter, while the coarser particles are returned to the grinding area for further grinding.

The performance of the classifier significantly impacts the overall efficiency of the VRM. Efficient separation leads to a narrower particle size distribution, ensuring that the final product meets the required specifications. Additionally, proper separation prevents the coarser particles from being overground, reducing energy wastage.

The mill body serves as the foundation of the entire VRM and houses all the essential components. It is constructed from heavy-duty materials to withstand the grinding forces and vibrations generated during operation.

As discussed earlier, the grinding table and rollers are crucial for material grinding. They are manufactured from wear-resistant materials to withstand the abrasive nature of the grinding process.

The drive system consists of an electric motor, gearbox, and drive shafts that rotate the grinding table and rollers. The power transmission from the motor to the mill is carefully engineered to ensure smooth and reliable operation.

The integrated classifier plays a key role in material separation. Its design and efficiency directly impact the product quality and fineness.

Our Projects

Copyright © ZENITH, All Right Reserved.