A stone mobile crusher in South Africa offers numerous benefits to the mining industry. Its mobility, versatility, and efficiency allow miners to save valuable time and money by crushing materials directly at the mining site. The elimination of transportation costs, along with reduced maintenance and downtime, leads to significant cost savings and improved productivity.

24 Online Service

In the realm of construction projects, time and money are two crucial factors that can make or break a venture. The advent of mobile crushing technology has revolutionized the industry by offering a cost-effective and efficient solution. Mobile crushing, through the use of portable crushers and screens, has become increasingly popular due to its ability to save both time and money.

One of the significant advantages of mobile crushing is the improved efficiency it brings to construction projects. In traditional methods, materials need to be transported to a fixed crushing site, resulting in delays and added costs. Mobile crushing eliminates the need for such transportation by bringing the crushers and screens directly to the construction site.

With mobile crushing equipment, contractors can quickly process materials on-site, reducing downtime associated with material transportation. This immediate access to crushing machinery allows for greater flexibility and enables construction projects to proceed swiftly. Whether it’s crushing concrete, rocks, or asphalt, mobile crushers can handle a variety of materials efficiently, ensuring a streamlined construction process.

The financial benefits of mobile crushing are undeniable. By eliminating the need for material transportation to a fixed crushing site, significant cost savings can be achieved. Traditional methods involve hiring trucks, drivers, and specialized machinery to transport materials, which can be expensive, especially for large-scale projects.

Mobile crushing equipment, on the other hand, brings the crushing process directly to the construction site, minimizing transportation costs. Furthermore, mobile crushers are versatile and can be used for multiple projects within a particular area, eliminating the need for repeated transportation expenses. This cost-effective approach allows construction companies to allocate their resources more efficiently and maximize their budget for other essential aspects of the project.

In addition to the time and financial benefits, mobile crushing also contributes to a reduced environmental impact. Traditional crushing methods often involve long-distance transportation, which results in increased fuel consumption and emissions. By minimizing the need for material transportation, mobile crushing reduces carbon footprint and air pollution associated with construction activities.

Moreover, mobile crushing facilitates the recycling and reuse of materials on-site. Concrete, asphalt, and other construction waste can be crushed and processed for use in new projects, reducing the demand for materials. This sustainable approach not only conserves natural resources but also promotes a circular economy in the construction industry.

Mobile crushing offers construction companies unparalleled versatility and adaptability. Portable crushers and screens can be easily transported to different project sites, allowing contractors to take advantage of opportunities without delay. Whether it’s a remote location or an urban setting, mobile crushing equipment can be swiftly set up and put into operation.

The flexibility of mobile crushing extends beyond the ability to move between sites. These portable machines can handle various types of materials, from concrete and asphalt to natural rock and demolition waste. Their adaptability ensures that contractors can tackle different projects with a single set of equipment, eliminating the need for multiple machines and further reducing costs.

The demand for stone materials in construction and infrastructure projects has surged in recent years, prompting the need for efficient and versatile mobile crushers. These powerful machines play a crucial role in processing various types of stones, providing the necessary raw materials for a multitude of applications. With numerous mobile crushers available on the market, it becomes essential to evaluate and determine which one is the best suited for stone crushing operations.

Mobile crushers are designed to crush stones on-site, eliminating the need for transportation from quarries to construction sites. They offer significant advantages in terms of flexibility, productivity, and cost-effectiveness. When selecting the best mobile crusher for stone, it’s crucial to consider several factors, including the type of stone, desired output, machine size, and mobility requirements.

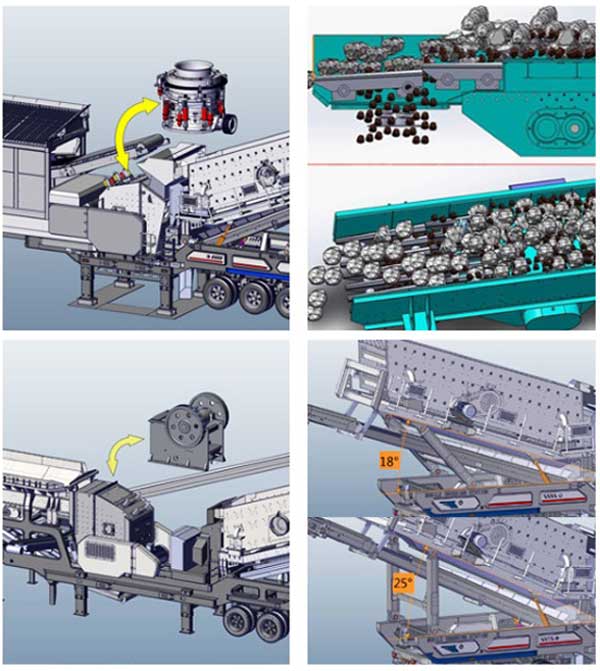

Jaw crushers are commonly used in the initial stages of stone crushing due to their ability to handle large rocks and high reduction ratios. These crushers employ a stationary jaw and a moving jaw to create a compressive force, breaking down the stones into smaller sizes. With their robust construction and reliable performance, jaw crushers are well-suited for various stone types and offer excellent efficiency.

Cone crushers excel at producing high-quality and uniform-shaped aggregates. These machines work by squeezing the stone between an eccentrically gyrating cone and a stationary outer concave. Cone crushers are particularly suitable for crushing hard and abrasive stones. They offer precise and adjustable crushing capabilities, making them ideal for producing fine aggregates used in concrete and asphalt production.

Impact crushers are renowned for their ability to produce high-quality cubic-shaped aggregates. They utilize a rapidly rotating rotor equipped with hammers or blow bars that impact the stone, breaking it into smaller pieces. Impact crushers are versatile machines that can handle various stone types and sizes. They are commonly used for recycling applications and in the production of road base materials.

Mobile crushers offer the advantage of mobility, allowing operators to transport the equipment easily between job sites. However, it’s essential to evaluate whether mobility is a critical requirement for your specific stone crushing operations. Stationary crushers, while lacking mobility, often offer higher processing capacities and greater stability. Consider the project scope and logistical aspects when deciding between mobile and stationary crushers.

Selecting the best mobile crusher for stone crushing operations requires careful consideration of various factors, such as stone type, desired output, machine size, and mobility requirements. Jaw crushers, cone crushers, and impact crushers each possess unique qualities that make them suitable for different applications. Ultimately, the best choice depends on your specific needs and priorities. By understanding the features and capabilities of different mobile crushers, you can make an informed decision to optimize your stone crushing operations for efficiency and versatility.

The extraction and processing of natural resources, particularly stones, are vital for various industries. In recent years, the development of stone mobile crushing technology has revolutionized the way stones are processed, making it more efficient and environmentally friendly.

Stone mobile crushing involves the use of specialized equipment to break down large stones into smaller pieces suitable for various applications. This process is typically carried out at the quarry site or the location where stones are being extracted. The mobile crushing unit is equipped with a crusher, conveyor belts, and a vibrating screen, allowing for efficient crushing and screening operations on-site.

The primary crushing stage involves the use of a powerful crusher, usually a jaw crusher or an impact crusher. These crushers are designed to break down large stones into smaller, manageable sizes. The stones are fed into the crusher’s hopper, and the powerful jaws or hammers exert force to break them down. The crushed stones then move to the next stage through conveyor belts.

In the secondary crushing stage, the crushed stones undergo further reduction in size. This stage is crucial for achieving the desired product specifications. Depending on the requirements, different types of crushers, such as cone crushers or impact crushers, may be used to achieve the desired size reduction.

After the crushing stages, the crushed stones are screened to separate them into different sizes. A vibrating screen with multiple decks is employed for this purpose. The screen separates the stones based on their sizes, ensuring that only the required sizes proceed further in the process, while the oversize material is sent back to the crusher for further crushing.

Stone aggregates produced through mobile crushing are widely used in road construction projects. These aggregates serve as the base and sub-base materials, providing stability and durability to the road infrastructure.

Mobile crushing produces high-quality stones that are utilized in building and construction projects. The crushed stones can be used for concrete production, masonry, and as fill material for foundations and structural elements.

Crushed stones of different sizes can be used for landscaping and decorative purposes. They can be employed in the construction of pathways, gardens, and driveways, enhancing the aesthetic appeal of outdoor spaces.

In the realm of construction and mining industries, stone crushing is an essential process that involves the breaking down of large rocks into smaller ones, which can be further used for various purposes. Traditionally, this task was accomplished manually, requiring significant time and effort. However, with the advent of stone mobile crushers, the crushing process has undergone a revolutionary transformation. These innovative machines have not only enhanced efficiency but have also saved valuable time during the crushing process.

One of the key advantages of stone mobile crushers is their enhanced mobility. Unlike stationary crushers, which are fixed at a specific location, mobile crushers can be easily transported from one site to another. This mobility allows operators to bring the crushers directly to the source of the stones, eliminating the need for transportation and thereby saving significant time. Whether it is a quarry or a construction site, mobile crushers can be quickly set up and put into operation, reducing downtime and increasing productivity.

Stone mobile crushers enable on-site crushing, which eliminates the need to transport stones to a centralized crushing facility. This not only saves time but also reduces transportation costs and environmental impact. On-site crushing allows for immediate processing of the stones, eliminating the need for stockpiling and subsequent re-handling. Construction projects can benefit immensely from this feature as it enables a continuous workflow, resulting in faster completion times.

Stone mobile crushers are designed to handle a wide range of materials, from soft limestone to hard granite and everything in between. Their versatility allows them to be used in various applications, including road construction, building foundations, and aggregate production. By having a single machine capable of handling different types of stones, operators can save time that would have been otherwise spent switching between multiple crushers or equipment. The ability to adapt to different materials on the fly streamlines the crushing process and significantly reduces downtime.

Stone mobile crushers are equipped with advanced crushing mechanisms that ensure efficient and precise crushing. These crushers utilize powerful jaws or impactors to break down the stones into smaller sizes. The crushers are designed to apply sufficient force to crush the stones effectively while minimizing energy consumption. This efficiency translates into time savings as operators can process larger quantities of stones in a shorter duration. Additionally, the precise crushing mechanism reduces the need for secondary crushing, further saving time and resources.

Modern stone mobile crushers come equipped with advanced control systems that allow operators to monitor and control the crushing process in real-time. Through these systems, operators can adjust the crusher settings, monitor the feed rate, and track the overall performance of the machine. Real-time monitoring and control enable operators to optimize the crushing process, ensuring maximum efficiency and productivity. Moreover, in case of any issues or malfunctions, operators can quickly identify and resolve them, minimizing downtime and maximizing time savings.

Stone mobile crushers are designed with safety features to protect operators and maintenance personnel. These features include safety guards, emergency stops, and remote control operation. By prioritizing safety, mobile crushers minimize the risk of accidents and injuries, allowing operators to work with confidence and focus. Additionally, mobile crushers often have simplified maintenance requirements, with easy access to key components. This ease of maintenance reduces downtime for routine inspections and repairs, maximizing the time available for crushing operations.

South Africa is known for its abundant mineral resources, with such vast deposits of minerals, it is no surprise that the country is a leading global supplier of diamonds, gold, platinum, coal, iron ore, manganese, and many other minerals. The mining industry in South Africa plays a vital role in the country’s economic development, contributing significantly to its GDP and providing employment opportunities for thousands of people. To extract these valuable minerals efficiently and cost-effectively, the mining industry relies heavily on advanced equipment and machinery, such as stone mobile crushers.

A stone mobile crusher is a powerful tool that is used to crush large rocks and stones into smaller pieces. The mobile crusher has two types: wheeled and tracked, which allows it to move freely throughout the mining site. With this mobile crusher, miners can easily process the materials, eliminating the need for transportation and reducing the operational costs associated with it.

One of the significant advantages of a stone mobile crusher in South Africa is that it saves both time and money. Traditionally, miners have used fixed crushers, which require huge amounts of time and effort to set up and dismantle. Additionally, transporting the materials from the mining site to the crusher and then to the processing plant adds a significant cost to the operation. However, with a stone mobile crusher, miners can set up the equipment quickly and easily right at the mining site, eliminating the need for transportation.

Time is of the essence in the mining industry, and any delays can result in significant losses. The mobility of a stone mobile crusher allows miners to quickly move the equipment to different areas of the mining site, depending on the location of the rocks or stones to be crushed. This flexibility enables miners to optimize their operations, ensuring that the crushing process is conducted efficiently and without unnecessary delays.

Moreover, a stone mobile crusher is designed to handle a wide variety of materials, ranging from soft rocks to hard stones. This versatility is particularly beneficial in South Africa, where mining sites often contain a diverse range of minerals. By using a mobile crusher, miners can easily adjust the machine’s settings to match the specific hardness and size of the material, resulting in better crushing performance and higher productivity.

In addition to saving time, a stone mobile crusher also saves miners a substantial amount of money. As mentioned earlier, the elimination of transportation costs is a significant advantage. Instead of relying on trucks or conveyor belts to transport the materials, miners can crush them directly at the mining site. This not only reduces fuel consumption but also minimizes wear and tear on the transportation equipment, leading to lower maintenance and replacement costs.

Furthermore, the efficient operation of a stone mobile crusher helps minimize downtime and optimize productivity. Traditional fixed crushers often require frequent maintenance and repairs, which can halt production and result in financial losses. On the other hand, mobile crushers are designed for easy maintenance and can be serviced quickly, allowing miners to keep their operations running smoothly and without unnecessary interruptions.

The cost savings achieved through the use of a stone mobile crusher can be reinvested into other areas of the mining operation, such as hiring more skilled workers, improving safety measures, or implementing advanced technologies. This reinvestment can further enhance the overall efficiency and profitability of the mining site, ensuring long-term sustainability.

A stone mobile crusher in South Africa offers numerous benefits to the mining industry. Its mobility, versatility, and efficiency allow miners to save valuable time and money by crushing materials directly at the mining site. The elimination of transportation costs, along with reduced maintenance and downtime, leads to significant cost savings and improved productivity. As the mining industry continues to evolve and adapt to changing market conditions, the adoption of stone mobile crushers is likely to increase, driving further advancements in mining operations across South Africa.

Our Projects

Copyright © ZENITH, All Right Reserved.