The rock crusher has undoubtedly revolutionized numerous industries by enabling the efficient processing of ores and rocks. Its ability to break down large materials into smaller, more manageable sizes has paved the way for the extraction of valuable minerals, the creation of construction materials, and the production of aggregates for various purposes.

24 Online Service

In the realm of construction, mining, and quarrying, one of the most essential and robust pieces of equipment is the rock crusher. This machine plays a pivotal role in breaking down large rocks into smaller, more manageable sizes, facilitating various industrial processes. While the term “rock crusher” is commonly used, it encompasses a wide range of devices, each designed for specific tasks.

A rock crusher, also known as a stone crusher or stone-crushing machine, is a mechanical device that aids in the process of reducing large rocks into smaller, more manageable pieces. The primary objective of a rock crusher is to break down the rock material into usable aggregate for construction or industrial purposes.

Jaw crushers are the most common and traditional type of rock crushers. They feature a fixed plate and a movable plate, with the rock material being crushed between them. As the movable plate moves towards the fixed plate, the rock is gradually crushed into smaller sizes. Jaw crushers are highly versatile and can handle a wide range of materials, making them suitable for various applications.

Impact crushers, as the name suggests, use impact forces to crush rocks. They utilize a high-speed rotor that impacts the incoming rock material, causing it to break apart. Impact crushers can be further classified into horizontal shaft impact crushers and vertical shaft impact crushers, depending on the direction of the impact force. These crushers are often used for producing finer aggregate and are widely employed in the mining and recycling industries.

Cone crushers are primarily used in the secondary and tertiary stages of crushing. They operate by compressing the rock material between a mantle and a concave, which causes the rock to break apart. Cone crushers are highly efficient and capable of producing high-quality aggregate with excellent particle shape. They are commonly used in the construction and mining industries.

Gyratory crushers are similar to cone crushers but have a different working principle. The rock material is fed into a conical-shaped chamber, and as it gets crushed, it falls out from the bottom. Gyratory crushers are preferred for high-capacity primary crushing and are commonly used in large-scale mining operations.

Rock crushers are essential in the construction industry as they are used to produce aggregate materials required for building roads, bridges, and structures. The crushed rock serves as a stable foundation and improves the overall durability and strength of construction projects.

In the mining industry, rock crushers are crucial for extracting valuable minerals from the ore. The crushed rocks are processed further to liberate the minerals, which are then separated and refined. Rock crushers are instrumental in enhancing the efficiency of mining operations by reducing the size of large rocks and facilitating mineral extraction.

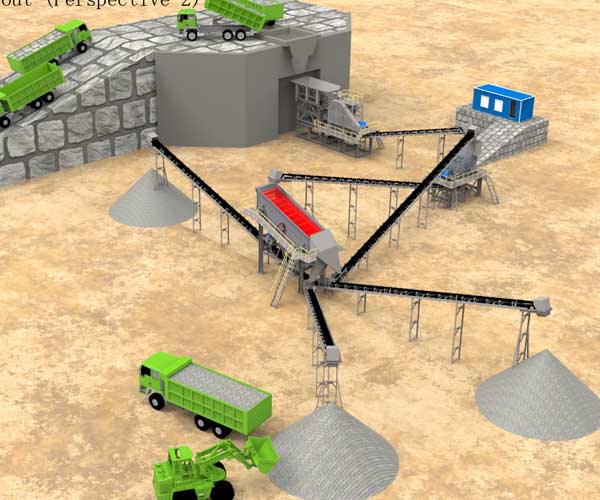

Quarries rely on rock crushers to process large quantities of rock materials for various applications. From producing crushed stone for construction projects to manufacturing asphalt and concrete, rock crushers are indispensable in the quarrying industry. They help extract raw materials efficiently and economically.

The field of rock crusher technology has witnessed significant advancements over the years. Manufacturers have developed innovative designs and incorporated advanced features to enhance the efficiency, safety, and productivity of rock crushers. These advancements include automated controls, improved crushing chambers, enhanced wear resistance, and optimized power consumption.

Rock crushers play a crucial role in the mining and construction industries, where they are employed to break down large rocks and ores into smaller, more manageable pieces. By applying mechanical force, rock crushers facilitate the extraction of valuable minerals and the creation of various construction materials. However, the choice of which ores and rocks can be effectively crushed by rock crushers depends on several factors, including hardness, abrasiveness, and composition.

Sedimentary rocks are formed through the accumulation and compaction of sediments over time. They often contain valuable minerals and are widely used in construction projects. While sedimentary rocks generally have lower compressive strengths compared to igneous and metamorphic rocks, they can still be effectively crushed by rock crushers. Limestone, sandstone, and shale are examples of sedimentary rocks frequently processed in rock crushers.

Igneous rocks are formed from the solidification of molten material, such as magma or lava. They possess diverse properties due to the different cooling rates and mineral compositions involved in their formation. Igneous rocks can range from highly resistant and hard rocks like granite to more brittle and less resistant rocks like basalt. Depending on their specific characteristics, different types of igneous rocks can be crushed by rock crushers.

Granite, a widely used construction material, requires robust rock crushers due to its high compressive strength and toughness. Basalt, on the other hand, is relatively easier to crush but still requires efficient machinery to break it down effectively. Other common igneous rocks crushed by rock crushers include diorite, gabbro, and rhyolite.

Metamorphic rocks are formed when existing rocks undergo changes in response to high temperatures and pressures. These rocks can have a diverse range of textures, mineral compositions, and strengths. Some metamorphic rocks are extremely hard and durable, while others may have weaknesses and cracks. Consequently, the crushing process for metamorphic rocks requires rock crushers capable of handling different levels of hardness.

Marble, a metamorphic rock widely used in construction and sculpture, is crushed using rock crushers that can handle its characteristic hardness. Quartzite, which is formed from sandstone and often used as a decorative stone, also requires specific crushers for effective crushing. Other metamorphic rocks, such as gneiss and schist, are processed similarly depending on their properties.

Apart from rocks used in construction, rock crushers are instrumental in extracting valuable minerals from ores. Various ores, including metallic and non-metallic ores, undergo crushing to liberate the desired minerals for subsequent processing. The choice of rock crushers for ore crushing depends on the target mineral and its physical properties.

Common metallic ores that require crushing include gold, silver, copper, iron, and lead-zinc ores. These ores often require crushers capable of handling high compressive strengths due to the presence of dense minerals and metallic compounds.

Non-metallic ores, such as phosphate rock, gypsum, and limestone, are also processed using rock crushers. However, the crushing requirements for non-metallic ores are often different from metallic ores, as they are generally softer and less abrasive.

Rock crushing is an essential process in various industries such as mining, construction, and aggregate production. It involves breaking down large rocks into smaller, more manageable pieces to facilitate further processing or use. The rock crushing process typically involves multiple stages, each serving a specific purpose in achieving the desired end product.

The primary crushing stage sets the foundation for subsequent stages and plays a vital role in the overall rock crushing process. It involves reducing the size of the initial rock by applying mechanical force through a primary crusher. Jaw crushers and gyratory crushers are commonly used in primary crushing operations. Jaw crushers work by compressing the rock against a fixed surface, while gyratory crushers use a rotating cone-shaped head.

The primary crushing stage aims to break down the rock into a manageable size for further processing. It typically produces a coarse aggregate with various sizes depending on the desired end product. Effective primary crushing ensures a more efficient utilization of downstream equipment and minimizes the risk of material blockages.

Following primary crushing, the rock undergoes secondary crushing to further reduce its size. Secondary crushers are employed to achieve this task, and they come in different types, including cone crushers, impact crushers, and roll crushers. Cone crushers are often used for their ability to produce a more uniform end product shape, while impact crushers excel at producing high-quality cubic aggregates.

Secondary crushing enhances the fragmentation process by breaking down the coarse aggregate from the primary stage into smaller, more refined particles. This stage is critical for achieving the desired particle shape, size distribution, and overall quality of the final product.

Tertiary crushing marks the final stage of the rock crushing process, where the rock is further reduced to its ultimate size and shape. Tertiary crushers, such as vertical shaft impactors (VSI) and high-pressure grinding rolls (HPGR), are commonly employed for this purpose. These crushers produce finely crushed particles that are suitable for applications requiring specific product specifications, such as concrete production or asphalt manufacturing.

Tertiary crushing enables the production of fine aggregates, which are often used in specialized applications. It also helps to optimize the overall particle size distribution, ensuring the final product meets the desired requirements.

In some cases, a quaternary crushing stage may be incorporated into the rock crushing process. Quaternary crushers are used to further refine the material, producing even finer particles. This stage is often employed when a specific product shape or size distribution is required, such as in the production of sand for concrete or asphalt.

Quaternary crushing can be achieved using various equipment, including cone crushers, impact crushers, and vertical shaft impactors. The inclusion of this stage depends on the specific requirements of the application and the desired end product.

When it comes to the extraction of valuable minerals and the creation of construction materials, the importance of crushing cannot be overstated. One crucial piece of machinery that plays a significant role in this process is the rock crusher. With its remarkable ability to break down ores and rocks into smaller, more manageable sizes, the rock crusher has revolutionized various industries, ranging from mining and metallurgy to construction and manufacturing.

At its core, a rock crusher is a heavy-duty machine designed to crush large rocks and ores into smaller fragments. Whether it’s extracting valuable minerals like gold or silver from their ores, producing gravel for construction projects, or pulverizing rocks for various industrial purposes, the rock crusher serves as an essential tool in these processes. By applying mechanical force, these machines break down the raw materials, enabling them to be used in downstream applications.

The hallmark of a rock crusher is its high efficiency in crushing operations. This efficiency is primarily achieved through several key features and design principles:

Rock crushers operate based on the principle of compression crushing. The machine applies a force to break the rocks by squeezing them between two solid surfaces: the stationary concave surface and the movable mantle. As the rocks enter the crusher, they are gradually compressed and fractured, resulting in smaller fragments.

To enhance the efficiency, some rock crushers incorporate additional mechanisms such as jaw crushers or impact crushers. Jaw crushers work by exerting a compressive force on the rocks while impact crushers use the principle of impact to crush the material. These variations offer even greater flexibility, allowing operators to choose the most efficient method for their specific needs.

The incorporation of a high-efficiency rock crusher into mining and construction operations brings forth numerous benefits, including:

Our Projects

Copyright © ZENITH, All Right Reserved.