Crushing and grinding lay the foundation by breaking down the raw material into manageable pieces. Beneficiation is then employed to remove impurities, such as iron, mica, and feldspar, which can negatively impact the quality of the final product.

24 Online Service

Quartz, a mineral composed of silicon and oxygen atoms, is one of the most abundant minerals on Earth’s surface. Its widespread presence in the Earth’s crust ensures a variety of sources for this raw material, typically derived from mines and quarries. These sources can be found in a multitude of locations across the globe.

Quartz is most frequently sourced from quartz mines and sand quarries, where geological processes have concentrated significant deposits of this mineral. Quartz mines, often located in regions with extensive geological history, yield some of the purest and high-quality quartz. However, quartz can also be found in sand quarries, which contain a mixture of quartz and other minerals. These sources are equally important, especially for industrial applications where extremely pure quartz is not a strict requirement.

The extraction of quartz from mines and quarries is a meticulous process that involves several steps, from exploration to extraction. The key challenges in the extraction process relate to the geology of the deposit and the environmental impact.

Once the quartz is extracted, the next step in its journey involves transportation to a processing plant and thorough sorting and grading procedures. These are vital to ensure the raw material is suitable for its intended applications.

Raw quartz, upon reaching the processing plant, undergoes extensive sorting and grading to remove impurities and classify it based on intended applications.

These sorting and grading procedures are critical to ensuring the quality of the final product, as quartz’s various applications require different levels of purity and cleanliness.

From the glittering countertops in our kitchens to the intricate components of high-tech devices, quartz is ubiquitous. However, the journey from raw quartz to its refined forms is a complex process that involves several crucial stages.

The journey of quartz begins in the earth’s crust, where it forms as a result of geological processes. Quartz crystals, composed of silicon and oxygen atoms, are often embedded within rocks or sediments. Extracting these precious crystals is the first step in transforming raw quartz into a wide array of valuable products.

Crushing and grinding are the initial steps in this process. They are essential for liberating the quartz crystals from the host rock or sediment, breaking them down into smaller, more manageable pieces. This physical transformation serves several critical purposes:

The crushing process typically involves the use of crushers, which come in various types and sizes depending on the desired output. These crushers range from jaw crushers and cone crushers to impact crushers and gyratory crushers. After the initial crushing, grinding follows to further reduce the size of the material. This can be done using various grinding equipment, including ball mills and rod mills.

Once the quartz has been crushed and ground, it is ready for the next steps in processing. At this stage, the material is still far from being the pristine quartz products we commonly encounter in our daily lives. It contains impurities, minerals, and other substances that must be removed to achieve the desired purity and quality.

Beneficiation is a critical phase in the processing of quartz, focused on removing impurities that could negatively impact the quality and suitability of the final products. Common impurities found in raw quartz include iron, mica, feldspar, and other minerals. Each impurity has its own unique challenges when it comes to removal.

Iron impurities are a common issue in quartz, often causing discoloration and affecting the material’s electrical and optical properties. Various methods, including magnetic separation and chemical leaching, are employed to remove iron from the quartz.

Mica is a flaky mineral that can introduce unwanted textures and inconsistencies in quartz products. Techniques like froth flotation and screening are used to separate mica from quartz.

Feldspar is another mineral often found in association with quartz. It can be challenging to remove feldspar due to its similar physical properties. However, processes like flotation, electrostatic separation, or acid leaching can effectively separate the two minerals.

Beneficiation processes can be intricate, requiring a combination of mechanical and chemical methods to effectively remove impurities. These processes are essential to ensure the final quartz product meets the required standards for various applications, from the production of high-purity silicon for electronics to the manufacturing of glass and ceramics.

To unlock its full potential, quartz must undergo several stages of processing, including size reduction and shaping, chemical treatment and refinement, and ultimately, manufacturing into a wide range of products.

The initial step in transforming raw quartz into useful products is size reduction and shaping. Raw quartz typically arrives at processing facilities in the form of large chunks or boulders, which must be broken down into smaller, more manageable sizes and shaped into the desired forms.

Two primary methods are commonly employed in this stage: mechanical and thermal processes. Mechanical methods include crushing, grinding, and milling using various equipment such as ball mills, grinders, and crushers. Ball mills, for instance, are widely used for reducing quartz particles to finer sizes. These mills consist of rotating cylinders filled with grinding media like steel or ceramic balls, which crush and grind the quartz into smaller particles as the cylinder rotates.

Grinders, on the other hand, use abrasive surfaces or cutting edges to reduce quartz to the desired size. The choice of equipment and techniques depends on the specific requirements of the end product and the raw material’s characteristics.

Apart from mechanical processes, thermal methods like annealing and melting can be employed to shape quartz. Annealing involves heating the quartz to a specific temperature and then slowly cooling it, which can modify its physical properties and make it more suitable for certain applications. In contrast, melting and subsequent cooling can be used to produce quartz glass, which is transparent and finds applications in optics and laboratory equipment.

Once the raw quartz has been reduced in size and shaped, it often requires chemical treatments to improve its quality, enhance its properties, or remove impurities. These treatments are essential to tailor the material for specific applications.

Acid leaching is a common chemical treatment applied to quartz. It involves immersing the quartz in an acid solution, typically hydrochloric or sulfuric acid, to remove impurities or undesired minerals. Acid leaching can be particularly important when producing high-purity quartz for use in the electronics and semiconductor industries. The process results in a material known as high-purity quartz or HPQ, which is crucial in the manufacture of quartz wafers and crucibles.

Flotation is another refining process used to separate impurities from quartz. In this method, finely ground quartz is mixed with water and various chemicals to create a frothy mixture. Air bubbles are introduced into this mixture, attaching themselves to impurities and allowing them to float to the surface, where they can be skimmed off. This process is often used in the production of quartz sand for various applications, as it effectively separates impurities like feldspar and mica.

Quartz processing doesn’t stop at size reduction, shaping, and chemical refinement. It extends into the manufacturing of an array of quartz-based products, each with its distinct applications.

Silica sand is one of the most common products derived from processed quartz. It is utilized in various industries, including construction, glass manufacturing, and foundry work. Silica sand’s high silica content and granular structure make it ideal for use as a construction material, in the production of glass containers, and as a casting material in foundries.

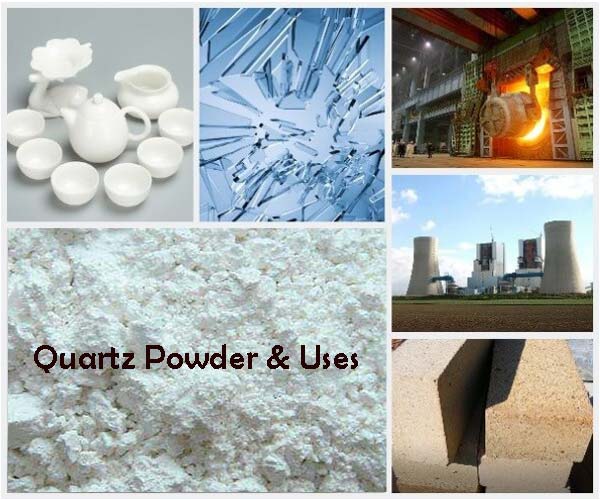

Quartz powder is produced through further grinding and milling of quartz particles, resulting in an ultra-fine powder. This fine powder finds applications in ceramics, paint production, and the manufacture of various composite materials. Its ability to improve the physical and chemical properties of products makes it an essential ingredient in many industrial processes.

Engineered quartz surfaces, often known by brand names like Caesarstone and Silestone, are created by mixing crushed quartz with resins and pigments. This mixture is then molded into slabs and subjected to a curing process. Engineered quartz surfaces combine the natural beauty of quartz with enhanced durability and flexibility, making them ideal for kitchen and bathroom countertops, wall cladding, and flooring.

The versatility of quartz products is evident in their extensive range of applications:

Our Projects

Copyright © ZENITH, All Right Reserved.