Mobile crushing and screening plants have revolutionized the mineral ore processing industry by offering a versatile and efficient solution for on-site ore processing. These plants find extensive applications in various mining operations, enabling operators to crush and screen mineral ores at the mining site itself.

24 Online Service

In today’s fast-paced world, the demand for construction materials and aggregates continues to rise, pushing the boundaries of traditional methods. Mobile crushing and screening plants have emerged as game-changers in the quarrying and mining industries, providing efficient and flexible solutions to meet the evolving needs of modern construction projects. These innovative machines combine the power of mobility with advanced crushing and screening technologies, offering significant advantages over stationary plants.

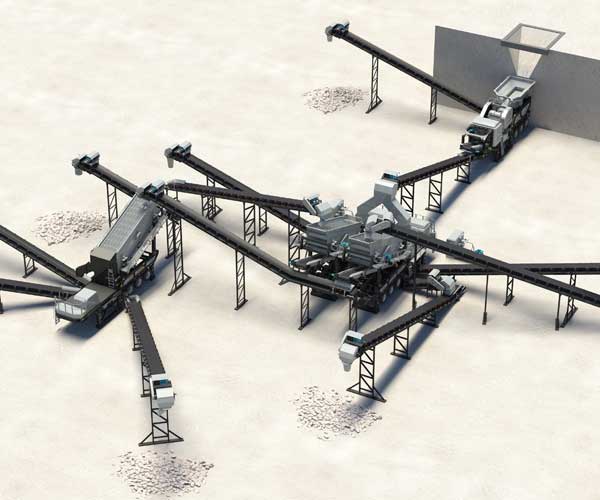

A mobile crushing and screening plant is a self-contained unit mounted on wheels or tracks, designed to crush and screen various types of rocks and minerals. These plants consist of a primary crusher for initial crushing and a secondary crusher for final processing, along with a vibrating screen unit for segregating the crushed materials based on size.

Mobile crushing plants utilize robust crushers that efficiently break down large rocks into smaller, more manageable sizes. The primary crusher, often a jaw or impact crusher, is responsible for reducing the initial material to a size suitable for further processing. The secondary crusher, such as a cone or impact crusher, further refines the material, transforming it into the desired end product.

Accompanying the crushing process is the screening unit, which separates the crushed materials into different fractions based on size. Vibrating screens with various mesh sizes ensure the precise segregation of the aggregates, making them suitable for specific applications.

The defining feature of mobile crushing and screening plants is their ability to move from one location to another. This mobility allows operators to bring the plant closer to the source of raw materials, reducing transportation costs and increasing operational efficiency. Moreover, it enables quick relocation between different job sites, enhancing project timelines and adaptability.

Mobile plants eliminate the need for expensive infrastructure and foundation works required for stationary installations. By eliminating these costs, operators can allocate their resources to other critical aspects of the project. Additionally, the ease of transportation and setup saves valuable time, enabling quicker project turnaround and reducing downtime.

Mobile crushing and screening plants are equipped with high-performance crushers and screens that deliver efficient processing capabilities. The advanced technologies employed in these machines ensure optimal productivity, allowing operators to produce a wide range of high-quality aggregates and materials.

With growing environmental concerns, mobile plants offer sustainable advantages over traditional stationary plants. The reduction in transportation distances decreases carbon emissions, contributing to a greener approach to operations. Furthermore, some mobile plants are designed to operate with low noise levels and are equipped with dust suppression systems, minimizing their impact on surrounding communities and ecosystems.

Mobile plants are extensively used in quarrying and mining operations, where they can process a wide range of materials, including limestone, granite, and ores. These plants enable efficient extraction of valuable minerals, providing a continuous supply of aggregates for construction and industrial purposes.

Mobile crushing and screening plants play a vital role in recycling construction and demolition waste. They can process demolished concrete, bricks, and other materials, transforming them into reusable aggregates for new construction projects. This recycling process not only conserves natural resources but also reduces the burden on landfills.

Mobile plants are often employed in road construction projects, where they produce high-quality aggregates required for asphalt and concrete. The ability to move the plant closer to the construction site eliminates the need for long-distance transportation of materials, making mobile plants a cost-effective solution.

Mobile crushing and screening plants are especially valuable in remote locations where access to traditional stationary plants is limited. These plants allow operators to carry out on-site processing, reducing dependency on external suppliers and streamlining operations in challenging environments.

Mineral processing plays a vital role in extracting valuable minerals from ores and rocks. One of the fundamental steps in this intricate process is crushing. Crushing is a mechanical operation that aims to reduce the size of large chunks of raw material into smaller particles, making them suitable for further processing.

Crushing is a crucial initial step in mineral processing, as it sets the stage for subsequent processing operations. The primary objective of crushing is to reduce the size of the raw material particles to a level where valuable minerals can be liberated and separated from the gangue (unwanted material). By breaking down the large chunks into smaller fragments, crushing increases the surface area of the ore, facilitating efficient extraction of the desired minerals.

Several methods are employed in mineral processing for the purpose of crushing. The selection of a particular method depends on various factors such as the type of ore, its physical properties, and the desired outcome. Here are some commonly used methods:

A range of equipment is utilized in the crushing process, each designed for specific applications. Some commonly used equipment includes:

Jaw Crushers:: Jaw crushers are primary crushers used for coarse crushing. They consist of a fixed plate and a movable plate, with the material being crushed between them. Jaw crushers are widely used in the mining and construction industries.

Cone Crushers:: Cone crushers are used for secondary and tertiary crushing. They operate by squeezing the material between a mantle and a concave. Cone crushers are commonly used in the mining and aggregate industries.

Impact Crushers:: Impact crushers are versatile machines used for primary, secondary, and tertiary crushing. They utilize impact force to crush the material and are widely used in the recycling, mining, and construction industries.

Gyratory Crushers: Gyratory crushers are used for primary crushing in large-scale mining operations. They consist of a conical-shaped head that gyrates inside a concave bowl, crushing the material against the stationary concave.

Mobile crushing and screening plants have revolutionized the mining, quarrying, and construction industries by offering efficient and flexible solutions for material processing on-site. These plants consist of various key components that work together to enhance productivity, reduce downtime, and improve the overall efficiency of the crushing and screening process.

The primary crusher is the heart of a mobile crushing and screening plant. It is responsible for reducing the size of the raw material extracted from the quarry or mine. Typically, jaw or impact crushers are used as primary crushers, depending on the nature of the material. These crushers break down the larger rocks into smaller, more manageable sizes, facilitating further processing.

The feeder is a crucial component that regulates the flow of material into the primary crusher. It ensures a steady supply of material, preventing overloading or underfeeding of the crusher. Vibrating grizzly feeders are commonly used in mobile plants, as they efficiently separate fines and scalps, enhancing the crusher’s performance and protecting it from unnecessary wear.

The scalper is another essential component of a mobile crushing and screening plant. It is responsible for removing oversized or coarse material before it reaches the crusher. By doing so, the scalper improves the efficiency of the primary crusher, reduces the risk of blockages, and enhances overall production. Scalpers can be equipped with various screening media, such as grizzly bars or punch plates, to suit the specific application.

The conveyor system is a critical link that connects different components of the mobile plant. It transports the crushed material from the primary crusher to secondary or tertiary crushers, screens, and stockpiles. These conveyors need to be robust, reliable, and capable of handling heavy loads. Additionally, they should be adjustable in height and length to accommodate different operational requirements.

Secondary and tertiary crushers are responsible for further reducing the size of the material processed in a mobile plant. These crushers are typically cone crushers or impact crushers. They play a crucial role in producing the desired end product size and shape. By utilizing multiple stages of crushing, mobile plants can achieve finer gradations and maximize product quality.

Vibrating screens are indispensable components of mobile crushing and screening plants. They separate the crushed material into different sizes according to specific requirements. Screens can have multiple decks, allowing for the classification of several products simultaneously. Efficient screening is vital for achieving the desired product quality, controlling the amount of fines, and maximizing overall plant capacity.

Stockpiling conveyors are responsible for stacking the processed material in various stockpiles for storage or further use. They provide flexibility in managing stockpiles of different sizes and configurations. These conveyors should have adjustable height and radial movement capabilities to create even and controlled stockpiles. Additionally, features such as telescopic functions and dust suppression systems are often incorporated to enhance operational efficiency and environmental compliance.

Mobile crushing and screening plants require a reliable and efficient power source to operate effectively, especially in remote locations. Diesel generators are commonly used to provide power for the entire plant. They ensure continuous operation and allow for easy relocation of the plant when necessary. Advanced monitoring and control systems are often integrated to optimize fuel consumption and minimize emissions.

The mining industry plays a vital role in the global economy, supplying essential raw materials for various sectors. Mineral ores are the backbone of modern infrastructure, serving as a source for metals, construction materials, and energy production. The process of extracting valuable minerals from their ores involves several stages, including crushing and screening. In recent years, mobile crushing and screening plants have gained significant popularity due to their versatility and efficiency.

Mobile crushing and screening plants are self-propelled machines designed to crush and screen mineral ores on-site, eliminating the need for transportation to a fixed processing plant. They consist of a mobile crusher unit, a vibrating screen, and a conveyor belt, which work together to process the ore efficiently. These plants are commonly used in mining operations, construction sites, and recycling applications due to their mobility and adaptability.

Iron ore is one of the most widely mined and processed minerals globally. Mobile crushing and screening plants are extensively used in iron ore processing for primary crushing and sizing of the ore. The ability to move the crushing and screening equipment close to the mining site reduces transportation costs and enables efficient processing, especially in remote locations.

Copper is a vital metal used in various industries, including electrical wiring, plumbing, and electronics. Mobile crushing and screening plants are employed in copper mining operations to reduce the size of copper ore and separate valuable minerals from gangue. By crushing the ore on-site, operators can minimize the transportation of bulky material, leading to cost savings and improved operational efficiency.

Gold has been a coveted metal throughout history and is still highly sought after for jewelry, investment, and industrial applications. Mobile crushing and screening plants play a crucial role in gold ore processing, enabling the extraction of gold from the ore by crushing it into smaller particles and separating the valuable metal through various techniques. The mobility of these plants allows for rapid deployment in different mining sites, increasing production flexibility.

Bauxite, the primary source of aluminum, undergoes a complex process to extract alumina, which is further refined into aluminum. Mobile crushing and screening plants are utilized in bauxite mining operations to crush and screen the ore, facilitating the removal of silica and other impurities. This process improves the quality of the bauxite ore and enhances the efficiency of the subsequent refining stages.

Mobile crushing and screening plants are also used extensively in the mining of limestone and production of aggregates for construction purposes. By crushing and screening limestone on-site, these plants provide a cost-effective solution for obtaining high-quality construction materials, eliminating the need for transportation from distant quarries.

Our Projects

Copyright © ZENITH, All Right Reserved.