Reliable and stable mill equipment is essential for efficient and high-quality barite grinding. The features discussed above, including robust construction, efficient grinding mechanisms, adjustable parameters, effective classification systems, reliable drive systems, advanced control and automation, easy maintenance and serviceability, and adequate safety features, contribute to the overall reliability and stability of the mill.

24 Online Service

Barite is a mineral commonly found in nature and used in various industries due to its unique properties. One of the primary applications of barite is in the oil and gas industry, where it is used as a weighting agent in drilling muds to control formation pressure. To meet the increasing demand for barite, efficient grinding equipment is essential.

Raymond mill, also known as Raymond roller mill, is a widely used grinding mill for various minerals. It is widely used in the fields of metallurgy, building materials, chemical industry, mining, and more. The grinding process of Raymond mill is achieved through a grinding roller and grinding ring. The material is fed into the grinding chamber between the grinding roller and grinding ring and is crushed and ground into a fine powder. Raymond mill has high efficiency, low energy consumption, and a relatively small footprint, making it a popular choice for grinding barite.

Ball mill is a common grinding equipment used in the mineral processing industry. It is mainly used for grinding various ores and other materials. In the case of barite grinding, the material is fed into the ball mill barrel, where it is finely crushed and mixed with steel balls of different sizes. The rotation of the barrel causes the steel balls to fall back onto the material, effectively grinding it into a fine powder. Ball mills are versatile and can grind barite to different sizes, depending on the desired application.

Vertical roller mill is a type of grinding mill that combines crushing, grinding, drying, and grading in one unit. It has high grinding efficiency, low power consumption, and low noise levels. In the case of barite grinding, the material is fed into the grinding mill, and the grinding roller presses the material against the grinding ring, which rotates at a high speed. The centrifugal force generated by the rotation of the grinding ring and the pressure of the grinding roller crush and grind the material into a fine powder. Vertical roller mills are suitable for large-scale production and are commonly used in barite grinding operations.

Ultrafine mill, also known as ultrafine grinding mill, is a grinding equipment developed for ultra-fine powder processing. It is suitable for grinding various non-metallic minerals with Mohs hardness below 7 and humidity below 6%. In the case of barite grinding, ultrafine mill can produce ultra-fine powders with a fineness of 325-2500 mesh. The material is fed into the grinding chamber and is impacted, rolled, and ground by the grinding roller and grinding ring. Ultrafine mill has the advantages of high grinding efficiency, low energy consumption, and low maintenance cost.

HGM micro powder mill is a new type of mill equipment developed by combining the advantages of the milling machine and the airflow mill. It can grind barite into a fine powder with a fineness of 325-3000 mesh. The material is crushed by the jaw crusher and then fed into the grinding chamber through the electromagnetic vibrating feeder. The material is continuously ground by the grinding roller and grinding ring under the action of the centrifugal force generated by the rotating turbine classifier. HGM micro powder mill has high grinding efficiency, low energy consumption, and good product fineness.

From oil and gas drilling to pharmaceuticals and paints, barite plays a crucial role in enhancing efficiency and performance. However, before it can be utilized effectively, barite must undergo a comprehensive crushing and grinding process.

Barite, often referred to as barytes, is found in sedimentary rocks and is commonly extracted from large deposits using surface or underground mining methods. It occurs in various colors, including white, yellow, brown, and gray, and possesses a high specific gravity, making it ideal for a multitude of industrial applications.

One of the primary uses of barite is in the oil and gas industry, where it is used as a weighting agent in drilling fluids. By adding barite to the drilling mud, its density is increased, which helps to control the pressure and prevent blowouts during drilling operations. The demand for barite in the energy sector has surged in recent years, driven by the growing exploration and production activities across the globe.

In addition to its role in the energy sector, barite is also utilized in the manufacturing of paints, rubber, plastics, and pharmaceuticals. Its high specific gravity provides excellent radiation shielding properties, making it valuable in the medical field for X-ray and gamma-ray protection. Furthermore, barite is a critical component in the production of barium carbonate, a chemical used in the glass and ceramics industry.

To unlock the full potential of barite, it must undergo a rigorous crushing and grinding process. The initial step involves extracting the mineral from the earth through mining operations. Depending on the location and size of the deposit, surface mining or underground mining methods may be employed.

Once the ore is extracted, it is typically crushed into smaller fragments to facilitate further processing. Crushing equipment such as jaw crushers, impact crushers, and cone crushers are commonly used to reduce the size of the ore particles. The crushed material is then transported to grinding mills for further refinement.

Grinding is a crucial step in the barite processing process, as it enhances the mineral’s fineness and unlocks its valuable properties. Various types of grinding mills are employed, including ball mills, Raymond mills, and vertical mills. These mills utilize different mechanisms, such as impact, attrition, and compression, to reduce the size of the barite particles further. The choice of grinding mill depends on factors such as the desired fineness, production capacity, and energy consumption.

During the grinding process, additives may be introduced to improve the efficiency and performance of the barite. These additives can include dispersants, grinding aids, and surface modifiers, which aid in the dispersion and flowability of the material. By optimizing the grinding parameters and utilizing suitable additives, the quality and properties of the final barite product can be tailored to meet specific industry requirements.

After the grinding process, the barite undergoes classification to separate the desired particle sizes. Various techniques, such as sieving, cyclones, and air classifiers, are used to achieve the desired particle size distribution. The classified material is then subjected to further processing, such as drying or chemical treatments, to meet the specific needs of different industries.

It is worth noting that the crushing and grinding process is not only aimed at achieving the desired particle size but also plays a crucial role in liberating valuable barite particles from impurities. The presence of impurities, such as quartz, calcite, and iron oxides, can adversely affect the quality and properties of the final product. Therefore, through careful processing, the impurities are minimized, resulting in a high-purity barite concentrate.

With its unique properties, barite has become an essential material in many manufacturing processes. To efficiently process and grind barite, reliable and stable mill equipment is crucial.

A reliable mill for barite grinding should have a robust construction to withstand the rigorous demands of the grinding process. It should be built with high-quality materials, such as durable steel, that can withstand heavy loads and resist wear and tear. A sturdy construction ensures the longevity of the mill and minimizes the risk of unexpected breakdowns or downtime.

Efficient Grinding Mechanism

The grinding mechanism of the mill should be designed to efficiently and effectively grind barite into the desired fineness. It should incorporate advanced technology, such as high-pressure grinding rolls (HPGR) or vertical roller mills (VRM), to achieve a fine and uniform grind. These mechanisms provide precise control over the grinding process, resulting in consistent particle size distribution and improved product quality.

A reliable mill should offer adjustable parameters that allow operators to optimize the grinding process according to specific requirements. The ability to adjust parameters such as grinding speed, pressure, and feed rate enables fine-tuning of the mill’s performance and ensures optimal grinding efficiency. This flexibility is particularly important for barite grinding, as different applications may require different particle sizes or product specifications.

A stable mill for barite grinding should have an effective classification system that separates the ground particles according to size. This classification system helps to ensure that the desired particle size distribution is achieved, and oversized particles are recycled back into the grinding chamber for further processing. By maintaining a consistent particle size, the mill can produce high-quality barite products that meet industry standards.

The drive system of the mill is responsible for transmitting power to the grinding mechanism. It is essential for this system to be reliable and provide consistent power delivery to ensure smooth and stable operation. Whether it is a gearless drive system or a traditional motor and gearbox arrangement, the drive system should be designed to handle the high torque and heavy loads associated with barite grinding.

The integration of advanced control and automation systems in mill equipment greatly enhances its reliability and stability. These systems enable real-time monitoring and control of various parameters, such as temperature, pressure, and power consumption, ensuring optimal operation and preventing potential issues. Additionally, automation reduces the reliance on manual intervention, minimizing the risk of human error and improving overall efficiency.

Easy Maintenance and Serviceability

A reliable mill should be designed for easy maintenance and serviceability. Components that are subject to wear, such as grinding rollers and liners, should be readily accessible for inspection and replacement. The mill should also include features that simplify maintenance tasks, such as quick-release mechanisms, modular design, and comprehensive documentation. Regular maintenance and prompt servicing can significantly extend the lifespan of the mill and minimize unplanned downtime.

Safety Features: Safety is paramount in any industrial setting, and mill equipment for barite grinding should be equipped with adequate safety features. These may include emergency stop buttons, safety interlocks, and protective guards to prevent accidents and protect operators. Proper safety training and clear operating instructions should also be provided to ensure the safe operation of the mill.

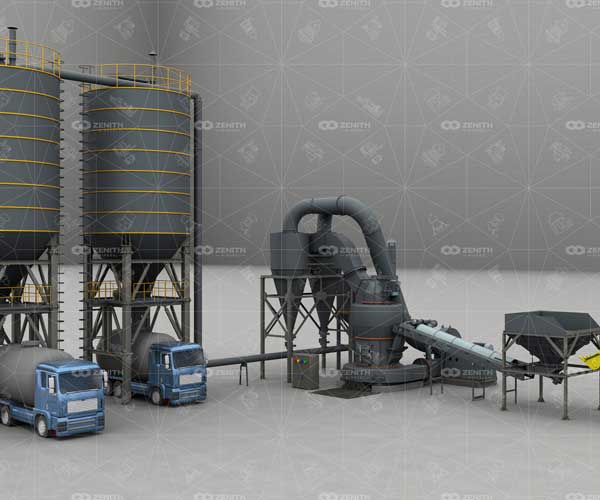

In today’s industrial landscape, the demand for high-quality materials with precise specifications is ever-increasing. Barite powder, derived from the naturally occurring mineral barium sulfate, has emerged as a vital ingredient in numerous industries. Its versatile properties make it an indispensable component in oil and gas drilling, paint and coating production, pharmaceuticals, rubber manufacturing, and many other sectors. To cater to this demand, the barite powder grinding mill line has become a crucial solution for processing barite into a finely ground powder that meets specific requirements.

Barite powder grinding plays a pivotal role in enhancing the properties and applications of this mineral. Raw barite, in its natural form, often possesses irregular shapes and sizes, rendering it unsuitable for direct use in various industries. The grinding process transforms the raw material into a finely ground powder, which exhibits improved flowability, dispersibility, and compatibility with other materials. Grinding also enables the precise control of particle size distribution, enabling manufacturers to achieve desired specifications, such as specific surface area and fineness.

One of the key applications of barite is in the production of barite powder, which finds extensive use in oil and gas drilling fluids, pharmaceuticals, rubber and plastic industries, and many others. To meet the increasing demand for high-quality barite powder, the barite Raymond mill has emerged as a crucial tool in the barite powder production line.

The barite Raymond mill is a specialized mill designed and manufactured by Zenith, a professional mining equipment manufacturer with more than 30 years of experience in the field. It is a high-efficiency and low-consumption milling equipment developed based on the traditional Raymond mill. The barite Raymond mill has outstanding advantages in terms of production capacity, energy consumption, and product fineness.

One of the significant advantages of the barite Raymond mill is its high production capacity. With the advanced milling principle and the optimized grinding roller and grinding ring structure, the mill can grind barite ore into high-quality powder with a fineness of 80-400 mesh. The production capacity of the mill can be greatly improved by adjusting the fineness of the finished product and the speed of the mill. This ensures that the barite powder production line can meet the needs of different industries for various fineness requirements.

In addition to its high production capacity, the barite Raymond mill is also known for its low energy consumption. The mill adopts a new energy-saving structure and advanced technology, which effectively reduces the power consumption of the mill system. Compared with the traditional mill, the energy consumption of the barite Raymond mill can be reduced by more than 30%. This not only reduces the production cost for enterprises but also contributes to environmental protection by reducing carbon emissions.

Moreover, the barite Raymond mill has remarkable advantages in terms of product fineness. The mill is equipped with a high-precision grading system, which can accurately control the particle size distribution of the finished product. The fineness of the barite powder produced by the mill can be adjusted arbitrarily within a certain range. This flexibility allows the mill to produce barite powder with different fineness according to the specific requirements of customers. The high product fineness ensures the excellent quality of the barite powder, making it highly valued in various industries.

Another significant feature of the barite Raymond mill is its stable performance and reliable operation. The mill adopts advanced technology and high-quality materials for its key components, ensuring the reliable operation of the equipment. The mill is also equipped with a complete set of intelligent control systems, which can monitor and control the operation of the mill in real time. This helps to prevent overload operation, improve equipment efficiency, and extend the service life of the mill.

Material: Barite

Capacity: 200,000TPY

Input Size: <38mm

Output Size: 250-400mesh

Daily Operation: 10h

Application: Weighing agent production

Equipment: A set of LM130 Mill

Daily Operation: 10h

Material: Barite

Input Size: 0-30mm

Output Size: 325mesh

Equipment: sets of MTW138 Grinding Mills

Our Projects

Copyright © ZENITH, All Right Reserved.