Lime powder grinding mills are essential machines in the lime production process, catering to diverse industrial applications in India. Each type of lime making machine possesses unique features, functionalities, benefits, and drawbacks, making them suitable for different production capacities and lime powder specifications.

24 Online Service

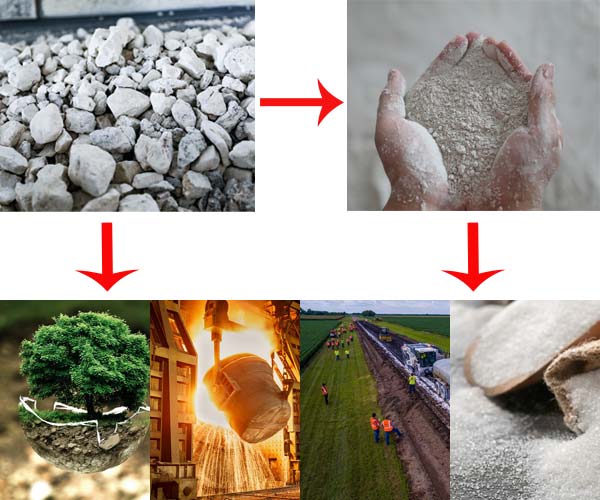

Lime, a versatile material derived from limestone, has become an indispensable component in a wide array of sectors, ranging from construction and agriculture to steel manufacturing and water treatment.

As the demand for lime across diverse industries continues to grow, the importance of high-quality lime powder cannot be ignored. Substandard lime not only compromises the end product’s performance but also poses significant risks to the environment and public health. Inadequate lime can lead to poor construction materials, reduced crop yields, subpar steel quality, and ineffective water treatment processes. Therefore, it is essential to prioritize the production of lime powder with consistent chemical composition and particle size, ensuring optimal performance across all applications.

To meet the escalating demand for high-quality lime powder, advanced lime making machines have become indispensable assets in the production process. Lime powder grinding mills are at the forefront of lime manufacturing, providing a finely ground and consistent product. These machines employ state-of-the-art technology to crush and grind limestone into a fine powder, thereby ensuring uniformity and purity.

The lime powder grinding mill operates through a series of grinding and classification stages, resulting in finely ground lime particles of desired size and chemical composition. Moreover, modern lime making machines incorporate dust control systems to mitigate environmental hazards and promote worker safety.

Lime powder, a versatile and essential industrial material, is widely used in various sectors such as construction, agriculture, chemical, and environmental industries. In India, lime making machines play a crucial role in producing high-quality lime powder efficiently. These machines are designed to crush limestone or other raw materials into fine powder, offering various types to cater to different lime production requirements.

The ball mill is one of the most common types of lime grinding machines used in India. It consists of a rotating cylinder filled with grinding media such as steel balls, ceramic balls, or rods. As the cylinder rotates, the grinding media crushes the limestone feed into fine lime powder. Ball mills are highly efficient and can produce uniform lime powder particles. They are suitable for both dry and wet grinding processes, making them versatile for various lime manufacturing applications.

Versatile for grinding different raw materials other than limestone.

Suitable for continuous operation, allowing for large-scale lime production.

Adjustable fineness of lime powder output.

The Raymond mill, also known as a pendulum mill, is widely used for fine grinding of limestone and other minerals. It operates by applying mechanical force to the material through rollers that move over a stationary grinding ring. The limestone feed is fed between the rollers and the grinding ring, resulting in the formation of fine lime powder.

The output size can be adjusted from 80 to 600 mesh, catering to different lime powder specifications.

Efficient air circulation and dust removal system, maintaining a clean operating environment.

Lower noise levels during operation.

The vertical roller mill (VRM) is a type of lime grinding machine that uses a combination of crushing, grinding, and classifying to produce lime powder. It comprises a rotating table and a set of grinding rollers that apply pressure on the material. The ground material passes through a dynamic separator, allowing only the fine lime powder to exit the system.

The hammer mill is a lime grinding machine that utilizes a series of rotating hammers to pulverize the limestone feed into a fine powder. The hammers strike the material with high-speed force, breaking it down until the desired lime powder size is achieved.

Lime powder, derived from limestone, has proven to be an indispensable resource in a wide range of industries due to its versatility, cost-effectiveness, and eco-friendly attributes. The lime powder grinding mill, an essential component in lime processing, plays a pivotal role in transforming raw limestone into fine powder, enabling its widespread use across various sectors in India.

The construction industry in India is one of the largest consumers of lime powder, utilizing it in both cement production and mortar preparation. Lime powder acts as a binding agent and enhances the strength, workability, and durability of concrete structures. It reduces the setting time of cement and also improves water retention in mortar, reducing cracks and enhancing overall structural integrity.

The construction of a high-rise commercial building in Mumbai exemplifies the successful application of lime powder grinding mills. The project used a significant amount of lime powder in concrete mixtures, resulting in superior-quality structures with increased longevity and reduced maintenance costs.

In the steel manufacturing process, lime powder is employed as a fluxing agent to remove impurities such as silica, phosphorus, and sulfur. It not only aids in achieving the desired chemical composition but also facilitates slag formation, which protects the molten steel from oxidation. Additionally, lime powder helps in controlling temperature during steel production, ensuring efficient and uniform heat distribution.

A prominent steel plant in Jamshedpur witnessed a substantial improvement in its steel quality and production efficiency after incorporating lime powder in their manufacturing process. The use of advanced lime making machines resulted in reduced energy consumption and increased overall productivity.

The sugar industry extensively utilizes lime powder in sugar cane juice purification. The addition of lime powder to the juice helps in neutralizing acidity and removing impurities like organic matters, proteins, and metal ions. This process results in clarified juice, which further enhances the efficiency of the evaporation process, leading to better sugar recovery.

A sugar mill in Uttar Pradesh witnessed a remarkable increase in sugar recovery rates by using lime powder in their juice purification process. The incorporation of a state-of-the-art grinding mill significantly improved lime powder quality, enabling better clarification and increased sugar yields.

Lime powder plays a crucial role in mitigating environmental challenges. In waste treatment plants, it is used to neutralize acidic wastewater, reducing harmful effluent discharge into water bodies. Lime powder is also an essential component in flue gas desulfurization (FGD) systems, where it reacts with sulfur dioxide emissions to produce calcium sulfate, a marketable byproduct, while reducing harmful air pollution.

A municipal wastewater treatment plant in Chennai achieved compliance with environmental regulations by adopting lime powder-based neutralization techniques. The implementation of a modern grinding mill resulted in better control over lime powder dosage and significantly improved pH levels in the effluent.

Agriculture in India benefits from lime powder’s agricultural applications. It is used to improve soil acidity and enhance nutrient uptake by crops. Lime powder also aids in the stabilization of soil for road construction, reducing soil plasticity and increasing load-bearing capacity.

A large-scale agricultural project in Punjab experienced a remarkable increase in crop yield and quality after incorporating lime powder into their soil treatment regime. This application resulted in improved soil structure and nutrient availability, leading to sustainable agricultural practices.

Lime is an essential material used in various industries, such as construction, agriculture, chemical manufacturing, and environmental applications. To meet this increasing demand, numerous manufacturers and suppliers have stepped forward to offer advanced lime making machines.

Zenith Machinery is a well-established manufacturer of lime making machines in India. With years of experience in the industry, they have gained a reputation for delivering high-quality equipment. Their lime making machines are known for their efficiency, durability, and ease of operation. Zenith Machinery offers a range of lime kilns and rotary lime kilns that cater to the diverse needs of lime producers.

Their rotary lime kilns are designed to produce high-quality lime with low energy consumption, making them environmentally friendly. These machines are equipped with advanced control systems, ensuring precise temperature and airflow management, resulting in consistent lime production. Customer reviews often praise Zenith Machinery’s excellent after-sales service and prompt technical support, which has contributed to their strong reputation in the market.

Technological advancements have been reshaping industries across the globe, and the lime production sector in India is no exception. Lime is a versatile material widely used in various industries, including construction, agriculture, and water treatment. Recent innovations in lime making machines have not only improved the efficiency and quality of lime production but also raised concerns about their environmental impact and safety considerations.

Lime making machines have undergone significant improvements in terms of automation, energy efficiency, and product quality. Some of the key innovations include:

Modern lime making machines are equipped with advanced automation and digital control systems. This allows for precise control over the production process, leading to consistent and high-quality lime output. Automated machines also minimize human intervention, reducing the risk of accidents and errors during production.

Traditional lime kilns were energy-intensive and contributed to environmental pollution. However, recent innovations have led to the development of energy-efficient kilns that use cleaner fuel sources and waste heat recovery systems. These advancements not only reduce operating costs for lime producers but also decrease the carbon footprint of the lime production process.

The grinding of limestone into fine lime powder is a critical step in the lime production process. Advancements in grinding technology have resulted in machines that can achieve finer particle sizes with lower energy consumption. This enhances the reactivity of lime, making it suitable for a broader range of applications.

Our Projects

Copyright © ZENITH, All Right Reserved.