Raymond roller mills are essential equipment in various industries, such as mining, construction, and chemical processing. These mills are widely used for grinding non-flammable and non-explosive materials with Mohs hardness below 9.3 and moisture content below 6%, such as limestone, calcite, barite, dolomite, potassium feldspar, and marble.

24 Online Service

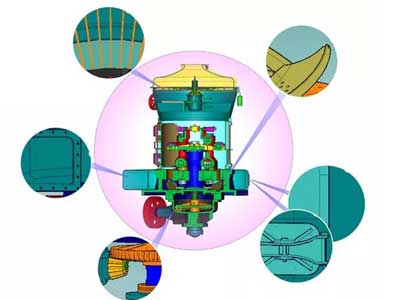

The Raymond roller mill, also known as the Raymond pulverizer or Raymond grinding mill, operates on the principle of compression and shear force. The raw material is fed between the grinding roller and the grinding ring, and as the grinding roller rotates, it applies pressure on the material, forcing it against the grinding ring. This pressure, combined with the centrifugal force generated by the rotating grinding ring, causes the material to be ground into fine particles.

Vertical roller mills and Raymond roller mills are both widely used grinding equipment in various industries, including mining, construction, and chemical processing. While they share similarities in terms of their vertical design and operational principles, these two types of mills also have distinct differences in their applications, material suitability, and performance characteristics.

Vertical roller mills (VRMs) are a type of grinding mill that relies on compression, shear, and friction forces between a set of rollers and a grinding table to pulverize various materials, such as cement raw materials, clinker, slag, coal, and minerals. They are widely used in the cement industry for raw material grinding, coal grinding, and finish grinding, as well as in power plants for coal pulverization and in other industries for mineral processing.

The Raymond roller mill, also known as the Raymond pulverizer or Raymond grinding mill, is a type of vertical roller mill specifically designed for the fine grinding of non-flammable and non-explosive materials with Mohs hardness below 9.3 and moisture content below 6%. These mills are commonly used in the processing of various minerals, such as limestone, calcite, barite, dolomite, potassium feldspar, and marble, among others.

Vertical roller mills are versatile and can process a wide range of materials, including cement raw materials, clinker, slag, coal, and minerals. They can handle materials with varying hardness and moisture content, making them suitable for a broader range of applications across different industries.

Raymond roller mills, on the other hand, are specifically designed for fine grinding of non-flammable and non-explosive materials with Mohs hardness below 9.3 and moisture content below 6%. This makes them more suitable for the processing of soft and medium-hard materials in the mineral processing industry.

Vertical roller mills are known for their ability to produce a wide range of particle sizes, from coarse to fine. They can be adjusted to produce the desired product fineness by controlling factors such as grinding pressure, grinding table speed, and classifier settings. This makes them suitable for applications that require adjustable product fineness, such as cement production and mineral processing.

Raymond roller mills, however, are specifically designed for fine grinding and are not well-suited for producing coarse products. They are known for producing a narrow range of particle sizes, with a focus on achieving high product fineness.

Vertical roller mills can dry materials during the grinding process, making them suitable for materials with higher moisture content. This is achieved by utilizing hot gases, such as waste heat from a kiln or hot air from a cooler, which are passed through the mill. This integrated drying capability allows for energy savings and simplifies the overall process, especially in industries such as cement production.

Raymond roller mills, on the other hand, are designed to handle materials with lower moisture content and do not have the same drying capabilities as vertical roller mills. This makes them less suitable for applications involving materials with high moisture content.

Vertical roller mills are known for their energy efficiency and high capacity, which makes them suitable for large-scale industrial applications. They can process large amounts of material with relatively low power consumption, making them an attractive option for energy-conscious industries.

Raymond roller mills, while still efficient, generally have lower capacity and higher specific energy consumption compared tovertical roller mills. This makes them more suitable for smaller-scale operations and applications that do not require the same level of throughput as larger installations.

Vertical roller mills tend to experience more wear and tear due to the high pressure and abrasive nature of the materials being processed. This results in a higher rate of wear on the grinding components, such as the rollers and the grinding table. As a result, maintenance costs and downtime can be higher in comparison to Raymond roller mills.

Raymond roller mills, on the other hand, experience relatively less wear due to the lower grinding pressure and the nature of the materials being processed. This leads to reduced maintenance costs and downtime, making them a more cost-effective option for certain applications.

Vertical roller mills offer greater operational flexibility, as they can be adjusted to accommodate a wide range of material properties and product requirements. They can be easily adapted to different feed materials, product specifications, and operating conditions, making them suitable for a wide range of applications across various industries.

Raymond roller mills, in contrast, are more specialized in their operation and are best suited for the fine grinding of specific materials with defined properties. They may not offer the same level of operational flexibility as vertical roller mills, which could limit their applicability in certain situations.

Cement production is a complex process that involves multiple stages, including raw material extraction, grinding, blending, heating, and cooling. The grinding process, in particular, plays a crucial role in determining the final product’s quality and performance. While vertical roller mills have traditionally been the go-to choice for cement grinding, Raymond roller mills have also found applications in this industry due to their unique features and capabilities.

The Raymond roller mill, a popular grinding equipment in the mineral processing industry, is known for its energy efficiency, fine grinding capabilities, and compact design. However, optimizing the efficiency of a Raymond roller mill can lead to improved productivity, reduced energy consumption, and enhanced product quality.

To improve the efficiency of a Raymond roller mill, it is essential to ensure that the material fed into the mill is consistent in terms of size, moisture content, and chemical composition. Irregularities in the material feed can cause uneven grinding, increased wear, and reduced performance. To optimize the material feed, consider implementing the following strategies:

The grinding pressure applied to the material by the grinding roller plays a crucial role in determining the efficiency of a Raymond roller mill. By adjusting the grinding pressure, you can control the fineness of the final product and the energy consumption of the mill. To optimize the grinding pressure, consider the following factors:

The classifier of a Raymond roller mill is responsible for separating the ground material based on particle size. By optimizing the classifier settings, you can improve the efficiency of the mill and ensure that the final product meets the desired specifications. To optimize classifier settings, consider adjusting the following parameters:

Proper airflow is essential for the efficient operation of a Raymond roller mill, as it transports the ground material from the grinding chamber to the classifier and eventually to the collection system. To maintain proper airflow, ensure that the following components are functioning correctly:

Routine maintenance and inspection are essential for maintaining the efficiency of a Raymond roller mill. By regularly inspecting and maintaining the mill, you can identify and address potential issues before they become significant problems. Key maintenance tasks include:

The efficiency of a Raymond roller mill is also influenced by the skill and knowledge of the operators. Well-trained operators can identify potential issues, make necessary adjustments, and ensure that the mill is running at its maximum efficiency. To improve operator performance, consider implementing the following strategies:

Improving the efficiency of a Raymond roller mill is a continuous process that involves optimizing material feed, adjusting grinding pressure, optimizing classifier settings, maintaining proper airflow, conducting regular maintenance and inspection, and training and educating operators.

By implementing these six methods, you can enhance the performance of your Raymond roller mill, leading to increased productivity, reduced energy consumption, and improved product quality. With a focus on continuous improvement and optimization, your Raymond roller mill can continue to provide exceptional grinding performance for years to come.

Our Projects

Copyright © ZENITH, All Right Reserved.