A pendulum roller mill is a type of grinding mill that is commonly used in industrial applications for size reduction and grinding of a wide variety of materials. This type of mill has been used for many years and has proven to be an effective and efficient means of grinding.

24 Online Service

The pendulum roller mill works by using a set of rollers that rotate around a central shaft. The rollers are held in place by a frame, and the material to be ground is fed into the mill through a hopper or chute. As the rollers rotate, they crush and grind the material between them, reducing it to a fine powder.

handle a wide variety of materials

One of the advantages of the pendulum roller mill is its ability to handle a wide variety of materials. These mills are commonly used to grind minerals such as limestone, gypsum, barite, and kaolin, as well as other materials such as coal, petcoke, and slag. The mill is also used for grinding food products such as grains and sugar, as well as chemicals and pharmaceuticals.

Another advantage of the pendulum roller mill is its low energy consumption. Compared to other types of mills, such as ball mills and vertical roller mills, the pendulum roller mill requires less energy to operate. This can result in lower operating costs for the user.

The pendulum roller mill also has a relatively simple design, which makes it easy to operate and maintain. The rollers can be easily removed for cleaning or replacement, and the mill can be easily disassembled for maintenance or repair.

In addition to its advantages, the pendulum roller mill also has some limitations. One of the main limitations is its relatively low throughput capacity. Compared to other types of mills, such as ball mills and hammer mills, the pendulum roller mill has a lower capacity for processing material. This can make it less suitable for applications that require high throughput rates.

Another limitation of the pendulum roller mill is its sensitivity to material hardness. If the material being ground is too hard, it can cause excessive wear on the rollers and other components of the mill. This can result in increased maintenance and repair costs, as well as decreased mill performance.

Despite its limitations, the pendulum roller mill remains a popular choice for many industrial applications. Its ability to handle a wide variety of materials, low energy consumption, and simple design make it a cost-effective and efficient means of grinding and size reduction.

Pendulum roller mills are commonly used in the mining and construction industries to grind materials into fine powder. These mills have been around for many years and have become increasingly popular due to their efficiency and versatility.other types of mills.

Pendulum roller mills consist of a large vertical drum that rotates around a central axis. The drum is suspended from an overhead support and is free to move in a circular motion. The drum is also equipped with a number of pendulums that are attached to the drum by means of springs. The pendulums are weighted and swing back and forth as the drum rotates, causing the material inside to be ground down into a fine powder.

The grinding process in a pendulum roller mill is very simple. The material to be ground is fed into the center of the drum and is thrown outward towards the edges by centrifugal force. As the material moves towards the edges, it comes into contact with the pendulums, which cause it to be ground down into a fine powder. The powder is then collected in a container at the bottom of the mill and is ready for use.

Pendulum roller mills, also known as vertical roller mills, are a type of grinding mill used extensively in the mining and cement industries. These mills have been in use for decades, but their importance has grown significantly in recent years due to advances in technology and the increasing demand for higher-quality products.

First and foremost, pendulum roller mills are used for the grinding and milling of raw materials in the cement industry. In cement manufacturing, raw materials such as limestone, clay, and iron ore are ground into a fine powder using a pendulum roller mill. This powder, called raw meal, is then heated to very high temperatures in a kiln to produce cement clinker. The clinker is then ground with a small amount of gypsum to produce cement.

The key advantage of using a pendulum roller mill in the cement industry is that it allows for a very fine grind of the raw materials. This is important because the finer the raw meal, the better the quality of the resulting cement. In addition, pendulum roller mills are able to grind materials with a wide range of particle sizes, which makes them ideal for use with a variety of different raw materials.

Another important application of pendulum roller mills is in the mining industry. In mining, these mills are used to grind and crush ore into small particles, which are then separated and processed to extract valuable minerals. The size of the particles produced by a pendulum roller mill can be controlled very precisely, which is important because different minerals require different sizes of particles to be efficiently extracted.

Pendulum roller mills are also used in the production of pigments, dyes, and other chemicals. In these applications, the mills are used to grind and disperse powders into liquids. This process is known as wet milling, and it is important because it allows for the production of very fine particle sizes, which can lead to better color and performance in the final product.

In the food industry, pendulum roller mills are used to grind and mill grains, such as wheat and corn, into flour. This process is critical for the production of many different food products, including bread, pasta, and baked goods. The ability of pendulum roller mills to produce a fine, uniform grind is essential for ensuring consistent quality in these products.

Finally, pendulum roller mills are also used in the pharmaceutical industry. In this industry, the mills are used to grind and pulverize active pharmaceutical ingredients (APIs) into fine powders that can be easily formulated into tablets, capsules, or other dosage forms. The ability to produce fine, uniform particle sizes is critical for ensuring the proper release of the API in the body, which is essential for its therapeutic effect.

Pendulum roller mill is a common grinding equipment used in mineral processing plants. It is a type of Raymond mill, which has been widely used in the grinding and milling industry for several decades. Pendulum roller mill can effectively improve grinding efficiency, reduce production costs, and improve product quality.

Pendulum roller mill can effectively improve grinding efficiency in the following aspects:

Pendulum roller mill can optimize the grinding process through the adjustment of the clearance between the grinding roller and the grinding ring. When the clearance is too small, the material cannot be effectively ground, and the grinding roller and the grinding ring will be severely worn. When the clearance is too large, the material will not be effectively ground, and the energy consumption will increase. Therefore, the optimal clearance between the grinding roller and the grinding ring can effectively improve the grinding efficiency.

Pendulum roller mill uses high-strength wear-resistant materials to make the grinding roller and the grinding ring. The use of high-strength wear-resistant materials can effectively improve the service life of the equipment and reduce the frequency of replacement of the grinding roller and the grinding ring. This can effectively reduce the downtime of the equipment and improve the grinding efficiency.

Pendulum roller mill uses a high-efficiency powder selection system to separate the qualified powder from the unqualified powder. The use of a high-efficiency powder selection system can effectively improve the grinding efficiency and reduce the energy consumption of the equipment.

Pendulum roller mill uses an advanced control system to control the grinding process. The use of an advanced control system can effectively improve the grinding efficiency, reduce the energy consumption of the equipment, and improve the product quality.

The MRN Pendulum Roller Grinding Mill is a cutting-edge technology in the world of grinding mills. This machine is designed to grind various kinds of materials, such as limestone, barite, kaolin, and slag, to produce high-quality powder with a high degree of fineness.

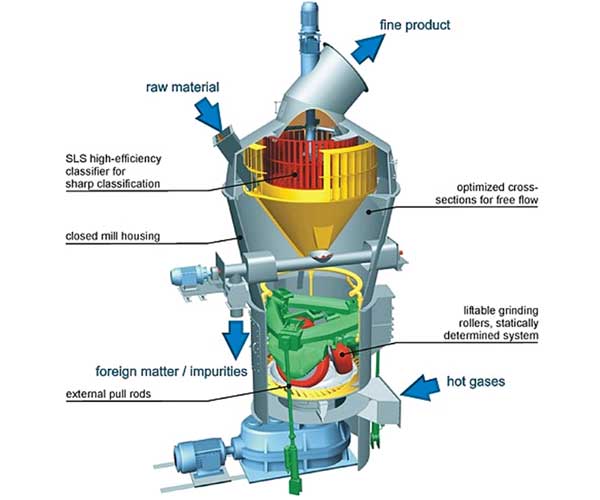

One of the unique features of the MRN Pendulum Roller Grinding Mill is its advanced grinding technology. This machine employs a pendulum grinding system that allows for uniform grinding of materials. This system consists of a grinding roller, grinding ring, and an electric motor. The grinding roller and grinding ring work together to create a highly efficient and effective grinding process. The electric motor provides power to the machine and allows for smooth and consistent operation.

Another advantage of the MRN Pendulum Roller Grinding Mill is its ability to produce high-quality powder with a high degree of fineness. This machine is capable of producing powder with a fineness of up to 400 mesh. This means that the powder produced by this machine is of high quality and can be used in a variety of industries. The high degree of fineness ensures that the powder is uniform and consistent, which is essential in many applications.

The MRN Pendulum Roller Grinding Mill is also highly efficient. This machine is designed to consume less energy than other grinding mills. The machine is also designed to operate at a low noise level, which is essential for many industries. The low noise level ensures that the machine can be operated in a variety of settings without disturbing other processes or workers.

The machine is also very easy to maintain. The grinding roller and grinding ring are made of high-quality materials that are designed to withstand the wear and tear of regular use. The machine also has a simple design, which makes it easy to clean and maintain. This ensures that the machine can operate at peak efficiency for longer periods without the need for frequent repairs or maintenance.

Another advantage of the MRN Pendulum Roller Grinding Mill is its versatility. This machine is capable of grinding a wide range of materials, which makes it an ideal choice for many industries. The machine is used in the production of cement, steel, and other industrial applications. It is also used in the production of cosmetics, food, and other consumer products.

The MRN Pendulum Roller Grinding Mill is also highly customizable. This machine can be configured to meet the specific needs of different industries. The machine can be fitted with various types of grinding rollers and grinding rings, which can be tailored to the specific needs of each industry. This ensures that the machine can be used in a variety of applications and can produce high-quality powder that meets the unique requirements of each industry.

Our Projects

Copyright © ZENITH, All Right Reserved.