A hammer crusher is a machine that uses rotating hammers to crush material into smaller pieces. It is commonly used in mining, cement, building materials, and other industries to crush hard, brittle materials such as limestone, coal, and ores.

24 Online Service

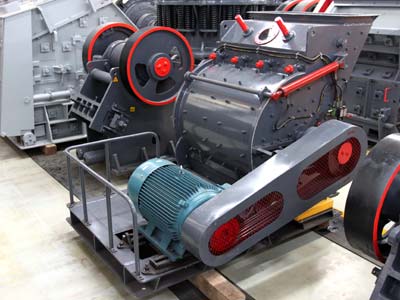

The hammer crusher consists of a rotor, a hammerhead, a counterattack liner, a sieve plate, and other components. The rotor is the main working part of the machine, and it rotates at high speed to crush the material. The hammerhead is the part of the rotor that strikes the material and crushes it into smaller pieces.

The material to be crushed enters the machine through a feed opening and is immediately impacted by the rotating hammers. The hammers strike the material with great force, causing it to break into smaller pieces. The crushed material then falls through a sieve plate and is discharged from the machine.

Hammer crushers are available in different sizes and models, depending on the application and the required capacity. They can be classified into single rotor and double rotor crushers. In a single rotor crusher, the hammers are arranged in a circular pattern on the rotor, while in a double rotor crusher, there are two rotors with hammers on each rotor.

One of the main advantages of a hammer crusher is its high crushing ratio, which means that the machine can process large amounts of material with a relatively low power consumption. This makes it ideal for use in industries where large quantities of material need to be processed.

Another advantage of a hammer crusher is its versatility. It can be used to crush a wide range of materials, including limestone, coal, and ores. It is also suitable for crushing materials of different hardness levels, from soft to hard.

Hammer crushers are also relatively easy to maintain. They have a simple design and are made from durable materials, which means that they can withstand heavy use without breaking down. In addition, most parts of the machine can be easily replaced, which makes maintenance and repairs relatively simple.

The output size of a hammer crusher refers to the particle size of the crushed material after being processed by the machine. It is typically measured in millimeters (mm) or micrometers (μm). The output size of a hammer crusher can vary depending on several factors, including the type of material being crushed, the size and shape of the hammers, the speed of the machine, and the size of the screen or grate through which the material passes.

The type of material being crushed is one of the most significant factors affecting the output size of a hammer crusher. Harder materials, such as granite or basalt, require more force to be broken down and typically result in larger output sizes. Softer materials, such as limestone or gypsum, can be crushed more easily and tend to result in smaller output sizes.

The size and shape of the hammers also play a role in determining the output size of a hammer crusher. The hammers are the primary crushing components of the machine and are responsible for delivering the crushing force to the material. Hammer crushers typically have multiple hammers, each with a different shape and size. The configuration of these hammers can be adjusted to control the output size of the machine.

The speed of the machine is another factor that can affect the output size of a hammer crusher. Higher speeds typically result in smaller output sizes, as the material is processed more quickly. Lower speeds can result in larger output sizes, as the material has more time to be crushed and broken down.

The size of the screen or grate through which the material passes is also a significant factor in determining the output size of a hammer crusher. Screens and grates can be adjusted to control the size of the particles that pass through them. Smaller screens and grates typically result in smaller output sizes, while larger screens and grates can result in larger output sizes.

In general, the output size of a hammer crusher can range from a few millimeters to several centimeters, depending on the factors outlined above. For example, a hammer crusher used to crush limestone may produce output sizes ranging from 10mm to 50mm, while a machine used to crush granite may produce output sizes ranging from 25mm to 100mm.

It is worth noting that the output size of a hammer crusher can also be affected by the moisture content of the material being crushed. Wet materials are more difficult to crush and can result in larger output sizes, while dry materials are easier to crush and can result in smaller output sizes.

It is typically used in the mining and construction industries to break down large rocks into smaller, more manageable pieces. However, not all rocks are suitable for this type of equipment.

First, it is important to understand the mechanics of a hammer crusher. The machine consists of a rotating shaft to which hammers are attached. The hammers are free to swing on the ends of the cross, or fixed, to the central rotor. The rotor rotates at high speeds within a chamber that contains the material to be crushed. As the hammers strike the material, it is broken down into smaller pieces that can be further processed.

The type of rock that is suitable for a hammer crusher is typically one that is relatively soft, such as limestone, shale, or sandstone. These types of rocks have a low hardness rating, which means that they can be easily crushed without causing excessive wear and tear on the machine. Additionally, they are often found in large quantities, making them a cost-effective option for many industries.

In contrast, harder rocks such as granite, basalt, or quartzite are not typically suitable for a hammer crusher. These rocks have a higher hardness rating and can cause significant damage to the machine if they are not properly handled. Furthermore, they are often found in smaller quantities, making them more expensive to process.

Another factor to consider when selecting rocks for a hammer crusher is the size of the material. Typically, a hammer crusher is designed to handle materials that are no larger than 6 inches in diameter. If larger rocks need to be crushed, a different type of crushing equipment, such as a jaw crusher or cone crusher, may be required.

In addition to the type and size of the rock, the moisture content of the material is also an important consideration. If the material is too wet, it can clog the crusher and cause it to malfunction. On the other hand, if the material is too dry, it can create excessive dust, which can be hazardous to workers and damaging to the machine.

The final consideration when selecting rocks for a hammer crusher is the intended use of the crushed material. For example, if the material will be used as a base for a road or building foundation, it will need to be crushed into very small pieces. In contrast, if the material will be used as a decorative stone or landscaping feature, it may only need to be broken down into larger chunks.

Ore crushing is an essential step in mining and mineral processing operations. It involves breaking large pieces of ore into smaller sizes for further processing. There are several types of machines used for crushing ore, and each has its unique features and benefits.

The gyratory crusher is another commonly used machine for crushing iron ore. It is similar to the jaw crusher in that it has a stationary mantle and a conical head that moves back and forth to crush the ore. The gyratory crusher is known for its high capacity and low operating costs. It is ideal for large-scale crushing operations.

Impact crushers are another type of machine used for crushing ore. They work by using a high-speed rotor to impact the ore against a stationary plate. This impact crushes the ore into smaller pieces, which are then sorted and processed. Impact crushers are commonly used for crushing soft to medium-hard materials, such as limestone, gypsum, and phosphate.

Hammer mills are also used for crushing ore. They consist of a series of hammers rotating around a central shaft. The ore is fed into the mill through a hopper and is crushed by the hammers as they rotate. Hammer mills are widely used in the mining industry for crushing hard and abrasive materials.

Iron ore is a mineral substance that is found in rocks and minerals from which metallic iron is extracted. Iron is the most widely used metal in the world, accounting for over 90% of the total metal production. It is used in the production of steel, which is an essential material for the construction of buildings, bridges, automobiles, and many other products. However, before iron can be used in steel production, it must be extracted from the earth, processed, and refined. One important tool in the iron ore processing industry is the hammer crusher.

Hammer crushers are machines that use a series of hammers to crush and disintegrate materials. They are widely used in many industries, including mining, construction, and demolition. In the mining industry, hammer crushers are used to crush and grind hard and abrasive materials, such as rocks, ores, and minerals, including iron ore.

Hammer crushers for iron ore are an important part of the iron ore processing plant. The hammer crusher works by using the high-speed rotating hammerhead to crush and disintegrate the materials fed into it. The hammerhead is made from cast steel and is abrasion-resistant, ensuring a long service life. The crusher is designed to have a large crushing ratio, which means that the product size is small and the output is high.

One of the key advantages of using a hammer crusher for iron ore is its cost-effectiveness. Compared to other types of crushers, such as jaw crushers and cone crushers, the hammer crusher has a lower upfront cost and a lower maintenance cost. This is because the hammer crusher is simple in design and does not have many moving parts, making it easier to maintain and repair.

Another advantage of the hammer crusher for iron ore is its versatility. It can be used for a variety of materials, including soft and hard rocks, ores, and minerals. This means that it can be used for both primary and secondary crushing. In addition, the hammer crusher can be used in a closed-circuit system, which means that the product is screened and sorted before it is discharged, ensuring that the product is of a consistent size.

The hammer crusher for iron ore is also environmentally friendly. It does not emit any harmful gases or pollutants, making it a safe and sustainable choice. In addition, the hammer crusher does not generate dust, which can be a problem in some other types of crushers.

One potential disadvantage of the hammer crusher for iron ore is its high power consumption. The hammer crusher requires a lot of energy to operate, which can result in higher electricity costs. However, this can be offset by the lower upfront cost and lower maintenance cost of the hammer crusher compared to other types of crushers.

Overall, the hammer crusher for iron ore is a cost-effective and versatile solution for the iron ore processing industry. It offers a number of advantages over other types of crushers, including its low upfront cost, low maintenance cost, and versatility. However, it is important to weigh these advantages against the potential disadvantages, such as its high power consumption. Ultimately, the choice of crusher will depend on a number of factors, including the size and type of the iron ore deposit, the desired product size, and the overall cost-effectiveness of the solution.

Our Projects

Copyright © ZENITH, All Right Reserved.