The gypsum powder production line is a well-choreographed symphony of machinery, with each component playing a vital role in the transformation of raw gypsum into a valuable industrial product. Understanding the functions and significance of crushers, mills, calciners, dust collectors, conveyors, and packaging units is essential for achieving efficiency, maintaining quality, and ensuring a safe working environment in this intricate manufacturing process.

24 Online Service

Gypsum powder begins with the mining of gypsum ore. This raw material is extracted from mines and quarries, where large deposits of gypsum are found. Once the gypsum ore is obtained, it undergoes a series of processing steps to transform it into the fine powder that serves as the foundation for a myriad of applications.

Gypsum deposits are typically found near the surface, making mining a relatively straightforward process. The extracted gypsum ore is then transported to processing plants for the next stages.

The mined gypsum ore is crushed into smaller pieces to facilitate further processing. Grinding mills are employed to reduce the size of the crushed ore into a fine powder. This step is crucial in achieving the desired particle size for various applications.

The ground gypsum undergoes calcination, a process where it is heated to remove excess water molecules. This step results in the formation of hemihydrate or stucco, a partially dehydrated form of gypsum. The calcination process is essential for enhancing the powder’s setting properties.

The stucco is then dried to eliminate any remaining moisture. The drying process is critical in ensuring the stability and quality of the final gypsum powder.

The dried stucco is finely ground into the desired powder consistency. The final product is then packaged for distribution and use in various industries.

One of the primary applications of gypsum powder lies in the construction industry. Its unique properties make it an indispensable material in the creation of durable and fire-resistant structures.

Gypsum powder is a key component in the production of drywall and plaster. When mixed with water, it forms a paste that can be applied to walls and ceilings, providing a smooth surface for painting or wallpapering. Drywall, also known as gypsum board, is widely used in modern construction for its fire-resistant and soundproofing qualities.

Gypsum is utilized in the production of Portland cement, acting as a retarder to control the setting time of the concrete. This ensures that the cement mix remains workable for a sufficient period, allowing for proper placement and finishing.

Gypsum powder is employed in soil stabilization to improve the structure and fertility of the soil. It helps in reducing soil erosion and enhances water infiltration, making it a valuable additive in road construction and agricultural projects.

Beyond construction, gypsum powder plays a vital role in agriculture, contributing to soil health and crop yield enhancement.

Gypsum is applied to soils as a natural conditioner. It helps improve soil structure by breaking up compacted clay soils and enhancing drainage in heavy, waterlogged soils. This creates an optimal environment for root growth and nutrient absorption by plants.

Gypsum is a source of calcium and sulfur, two essential nutrients for plant growth. Its application helps address nutrient deficiencies in the soil, promoting healthier and more robust crop development.

Gypsum is effective in mitigating the impact of saline soils on agriculture. It aids in leaching excess salts from the soil, making it more suitable for crop cultivation.

Apart from construction and agriculture, gypsum powder finds applications in various other industries due to its versatile properties.

Gypsum is used in the food and beverage industry as a calcium supplement and firming agent. It is added to certain foods to improve texture and stability.

The pharmaceutical industry utilizes gypsum in the production of medicines and supplements. Gypsum’s binding properties make it a valuable ingredient in tablet formulation.

Gypsum’s sculptural versatility extends to the art world. Artists and sculptors use gypsum powder as a primary material for creating intricate sculptures and art installations.

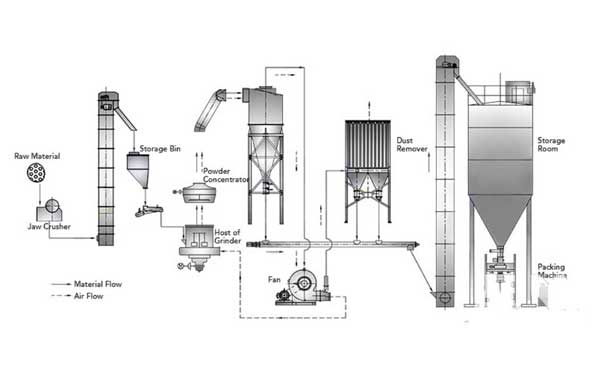

The gypsum powder production line is a complex process that involves several key components working in tandem to transform raw gypsum into a fine powder suitable for various industrial applications. Understanding the intricate details of each stage is crucial for optimizing efficiency and ensuring a high-quality end product.

The journey begins with the crushing stage, where raw gypsum is broken down into smaller, manageable pieces. Crushers play a pivotal role in this phase by employing various mechanisms to reduce the size of the raw material. Common types of crushers used in gypsum powder production include jaw crushers, impact crushers, and cone crushers.

Primarily used for coarse crushing, jaw crushers exert pressure on the gypsum, breaking it down into smaller pieces. This initial reduction is crucial for the subsequent stages of the production line.

Operating on the principle of impact, these crushers use rapid collisions to break the gypsum into smaller fragments. They are effective for both primary and secondary crushing.

Ideal for fine crushing, cone crushers further reduce the gypsum particles, producing a uniform size suitable for the grinding stage. Their precision makes them essential for achieving the desired powder consistency.

Once the raw gypsum is sufficiently reduced in size, it enters the grinding stage, where mills take center stage. Mills are pivotal in reducing gypsum to a fine powder through a meticulous milling process.

Widely used in gypsum powder production, ball mills consist of rotating cylinders filled with grinding media. As the cylinder rotates, the media crushes the gypsum into a fine powder. The speed of rotation and the size of the grinding media influence the fineness of the resulting powder.

Known for their high efficiency, Raymond mills use centrifugal force to grind gypsum between stationary rollers and a rotating grinding ring. The adjustable classifier controls the product’s fineness, making it a versatile choice for gypsum milling.

The calcination stage is a critical step in the gypsum powder production process, where water is removed from the crushed and ground gypsum to create the final product. Calcination involves subjecting the gypsum to high temperatures in a controlled environment, driving off excess water and converting calcium sulfate dihydrate to calcium sulfate hemihydrate.

These high-temperature vessels are integral to the calcination process. Gypsum enters the calciner, and as it travels through, the intense heat causes the release of water molecules, leaving behind the desired hemihydrate. The efficiency of calciners directly influences the quality of the final gypsum powder.

Maintaining a clean and safe production environment is paramount, and dust collection systems play a crucial role in achieving this. Gypsum powder production generates airborne particles that can be harmful if not properly managed.

Widely employed in gypsum powder production, baghouse dust collectors use fabric filter bags to capture and filter dust particles. This ensures that the air released from the production line is clean and free of contaminants.

Cyclone Separators: Operating on the principle of centrifugal force, cyclone separators separate dust from the air stream by causing particles to move to the outer wall and then fall into a collection hopper. They are effective for coarse dust particles.

The final stages of the gypsum powder production line involve conveying the processed material between different components and packaging the end product for distribution and use.

Essential for streamlining the production process, conveyors transport materials between various stages of the production line. They ensure a continuous flow of gypsum from crushing to calcination and, finally, to packaging.

The last step in the journey, packaging, involves carefully weighing and sealing the gypsum powder into bags or containers suitable for transportation and use. Precision in packaging is crucial to meet industry standards and customer expectations.

Our Projects

Copyright © ZENITH, All Right Reserved.