Rock crushing is an essential process in many industries, including mining, construction, and demolition. The process involves breaking down large rocks into smaller pieces that can be used for a variety of purposes, such as building materials or landscaping.

24 Online Service

Traditional rock crushing methods can be time-consuming and inefficient, leading to increased costs and reduced productivity. High efficiency rock crushing is a solution to these problems, providing faster, more reliable, and more cost-effective rock crushing processes.

High efficiency rock crushing technology utilizes specialized equipment and techniques that are designed to improve the efficiency of the crushing process. This technology can involve the use of a variety of machines, such as jaw crushers, cone crushers, and impact crushers, all of which are designed to break down rock into smaller pieces quickly and efficiently. In addition, high efficiency rock crushing can involve the use of advanced automation systems that monitor and control the crushing process to ensure optimal performance and productivity.

One of the primary benefits of high efficiency rock crushing is improved productivity. Traditional rock crushing methods can be time-consuming and require significant manual labor, which can slow down the overall production process. By using specialized equipment and automation systems, high efficiency rock crushing can significantly reduce the time and labor required for rock crushing, allowing companies to increase their productivity and profitability.

In addition to improved productivity, high efficiency rock crushing can also lead to cost savings. Traditional rock crushing methods often require significant amounts of energy and resources, such as fuel and water, which can be expensive. High efficiency rock crushing utilizes specialized equipment and techniques that are designed to minimize energy consumption and reduce the amount of resources required, resulting in lower operating costs and improved profitability.

Another benefit of high efficiency rock crushing is improved safety. Traditional rock crushing methods can be hazardous, with workers often exposed to dangerous equipment and materials. By using specialized equipment and automation systems, high efficiency rock crushing can reduce the risk of accidents and injuries, improving worker safety and reducing the risk of costly lawsuits and legal liabilities.

Granite is a type of igneous rock that is formed by the slow crystallization of magma deep beneath the earth’s surface. It is an incredibly durable and resilient material that is used in a variety of applications, including construction, architecture, and landscaping. However, before granite can be used in these applications, it must be processed and shaped using specialized equipment, including granite crusher machines.

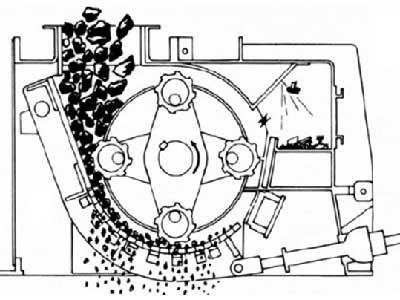

Granite crusher machines are large pieces of machinery used to crush and grind granite rocks into smaller pieces. These machines have a cone-shaped crushing chamber that is lined with a durable, high-density material. The granite rocks are fed into the crushing chamber through a hopper and then crushed by the rotating blades of the crusher.

One of the most important components of a granite crusher machine is the rotor. The rotor is a large, cylindrical component that rotates at high speed and is responsible for crushing the granite rocks. The rotor is made up of several blades or hammers that are arranged in a spiral pattern along the length of the rotor. As the rotor spins, the blades or hammers strike the granite rocks, crushing them into smaller pieces.

Another important component of a granite crusher machine is the feed plate. The feed plate is a flat, rectangular piece of metal that is mounted on the top of the crusher. It serves as a guide for the granite rocks as they are fed into the crushing chamber. The feed plate is designed to direct the rocks into the center of the crushing chamber, where they are crushed by the rotating blades of the crusher.

The crushed granite rocks then pass through a series of screens that are designed to separate the different sizes of rocks. The screens are made up of several layers of mesh that are arranged in a series of decreasing sizes. The larger rocks are retained on the top layer of mesh, while the smaller rocks pass through to the lower layers. This process ensures that the different sizes of rocks are separated and can be used for different applications.

Once the rocks have been separated by size, they are transported to different parts of the processing plant for further processing. Some of the larger rocks may be used for landscaping or construction, while the smaller rocks are used as aggregate for concrete or asphalt. The finer particles of granite may also be used as a filler in the manufacturing of various products, such as paints, plastics, and ceramics.

Granite crusher machines are an essential part of the granite processing industry. Without these machines, it would be impossible to efficiently process and shape the granite rocks that are used in a variety of applications. These machines are designed to be durable, reliable, and easy to maintain, ensuring that they can handle the demands of the granite processing industry for many years to come.

Crushers are essential machines in the mining, quarrying, and construction industries. They are designed to reduce the size of large rocks, gravel, or other materials into smaller, more manageable pieces. The efficiency of a crusher is a critical factor in determining its effectiveness and value.

Crushing efficiency is a measure of how effectively a crusher reduces the size of the material it is processing. The goal of any crusher is to reduce the size of the material to a level that can be further processed or used in the desired application. The efficiency of a crusher is determined by several factors, including the type of crusher, the size of the feed material, the size of the product, and the rate of production.

There are several ways to measure the efficiency of a crusher, but the most common is the reduction ratio. The reduction ratio is the ratio of the size of the feed material to the size of the product. For example, if the feed material is 8 inches and the product size is 1 inch, the reduction ratio is 8:1.

Another common way to measure the efficiency of a crusher is through the use of the Bond Work Index. The Bond Work Index is a measure of the energy required to grind a material in a ball mill. It is commonly used to determine the efficiency of crushers and grinding mills. The higher the Bond Work Index, the more energy required to crush the material, and the less efficient the crusher.

The efficiency of a crusher is important for several reasons. First, a more efficient crusher will require less energy to operate, reducing energy costs and improving the overall sustainability of the operation. Second, a more efficient crusher will produce more product at a lower cost, improving the profitability of the operation. Finally, a more efficient crusher will produce less waste material, reducing the environmental impact of the operation.

There are several factors that can affect the efficiency of a crusher. These include the type of crusher, the size of the feed material, the size of the product, and the rate of production.

Different types of crushers have different efficiency levels. For example, a jaw crusher is typically more efficient than a gyratory crusher because it has a lower reduction ratio and is better suited to handle softer materials. Conversely, a cone crusher is typically more efficient than a jaw crusher when processing harder materials.

The size of the feed material is another important factor in determining crusher efficiency. Larger feed materials typically require more energy to crush and can result in lower efficiency levels. It is important to match the size of the feed material to the appropriate crusher to achieve maximum efficiency.

The size of the product is also an important factor in crusher efficiency. A smaller product size typically requires less energy to produce and can result in higher efficiency levels. However, it is important to balance the size of the product with other factors, such as the desired end use and the cost of production.

The rate of production is the final factor that can affect crusher efficiency. A higher production rate typically requires more energy to produce, which can result in lower efficiency levels. It is important to balance the rate of production with other factors, such as the size of the feed material and the desired end use.

Rocks have been a significant part of our lives for centuries. They are found everywhere, and their uses are numerous, ranging from construction to decoration. However, before rocks can be used for any purpose, they must be crushed into smaller pieces. The machine used for this purpose is known as a rock crusher.

A rock crusher is a machine designed to break large rocks into smaller rocks, gravel, sand, or rock dust. There are several types of rock crushers, each designed for a specific purpose. Some of the most common types of rock crushers include jaw crushers, cone crushers, gyratory crushers, and impact crushers.

Jaw crushers are the most commonly used rock crushers. They are designed to crush rocks of various sizes and shapes using two plates, one of which is stationary, and the other moves back and forth. The rocks are placed between the two plates, and as the movable plate moves back and forth, the rocks are crushed into smaller pieces.

Cone crushers, on the other hand, are designed to crush rocks using a rotating mantle that gyrates within a concave bowl. The rocks are fed into the bowl through an opening, and as the mantle rotates, it crushes the rocks into smaller pieces. Cone crushers are commonly used for secondary and tertiary crushing.

Gyratory crushers are similar to cone crushers, but they have a different design. Gyratory crushers consist of a stationary mantle, which is located inside a concave bowl. The rocks are fed into the bowl through an opening, and as the mantle rotates, it crushes the rocks into smaller pieces.

Impact crushers, on the other hand, are designed to crush rocks using a rotor that spins rapidly. The rocks are fed into the rotor from the top, and as the rotor spins, it crushes the rocks into smaller pieces. Impact crushers are commonly used for crushing rocks that are softer or less abrasive.

Granite is a popular building material that is widely used in construction and landscaping projects. Granite is known for its durability, strength, and resistance to wear and tear. In order to process granite into usable aggregate, a granite crusher machine is required. A granite crusher machine is a high-efficiency rock crushing equipment that is used to crush granite, which can turn granite into various sized aggregates.

Granite crusher machines are available in various types, including jaw crushers, impact crushers, and cone crushers. Jaw crushers are primarily used for coarse crushing, while impact crushers and cone crushers are used for secondary and tertiary crushing. Each type of crusher has its own advantages and disadvantages, depending on the application.

One of the advantages of a granite crusher machine is its high efficiency. A high-efficiency granite crusher machine can effectively process granite into smaller aggregates at a faster rate, which reduces the time and cost required for processing. This can result in increased productivity and profitability for construction companies and contractors.

Another advantage of a granite crusher machine is its versatility. A granite crusher machine can be used to crush various types of rocks and stones, not just granite. This means that a granite crusher machine can be used for a wide range of applications, including road construction, building construction, landscaping, and more.

In addition to its high efficiency and versatility, a granite crusher machine is also durable and reliable. Granite crusher machines are built to withstand harsh conditions and heavy use. They are designed to last for many years without requiring frequent repairs or maintenance. This makes them an ideal investment for construction companies and contractors who need a reliable and durable crushing solution.

When choosing a granite crusher machine, it is important to consider the specific needs of the project. Factors to consider include the size of the granite aggregates required, the type of granite being crushed, and the location and accessibility of the project site. It is also important to choose a crusher machine that is compatible with other equipment on the job site, such as loaders and excavators.

Choosing the right rock crusher for a specific purpose depends on several factors, including the hardness of the rocks, the desired size of the crushed rocks, and the budget available. Jaw crushers are generally more affordable and are ideal for crushing rocks that are softer or less abrasive. Cone crushers are more expensive but are ideal for crushing rocks that are harder and more abrasive. Gyratory crushers are the most expensive but are ideal for crushing rocks that are very hard and abrasive.

In addition to the types of rock crushers mentioned above, there are also specialized rock crushers designed for specific purposes. For example, vertical shaft impact crushers are designed to crush rocks into cubical shapes, while horizontal shaft impact crushers are designed to crush rocks into a more elongated shape.

Our Projects

Copyright © ZENITH, All Right Reserved.