Ball mill prices in the Thai market are subject to fluctuations influenced by economic conditions, currency exchange rates, raw material costs, competition, and regulatory factors. Buyers should conduct thorough research and consider their specific needs when making purchasing decisions.

24 Online Service

In the world of mechanical engineering and materials science, few pieces of equipment are as ubiquitous and indispensable as the ball mill. This unassuming device, with its deceptively simple design, plays a pivotal role in numerous industrial processes, from pharmaceuticals to mining, ceramics to metallurgy.

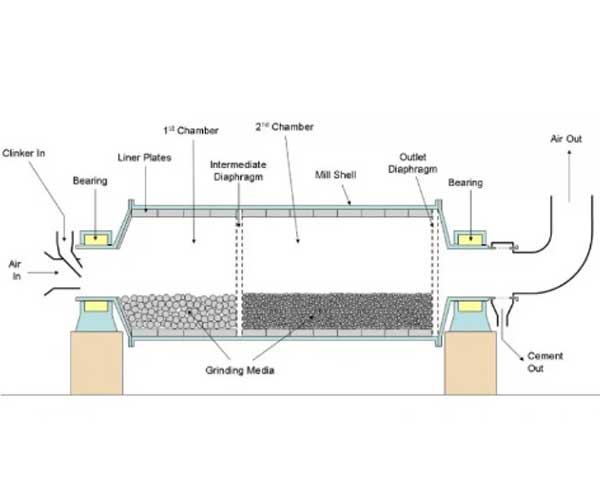

At its core, a ball mill is a cylindrical machine designed to pulverize or grind materials into fine powders. The primary purpose of a ball mill is to reduce the size of solid particles, making them more accessible for subsequent processing or to create homogeneous blends of different materials. It achieves this through the application of mechanical force and energy.

The operation of a ball mill can be understood in three key stages: loading, grinding, and unloading.

The process begins with the introduction of raw materials into the drum or container of the ball mill. These materials can vary widely, from ores and minerals to pigments and chemicals. To ensure a consistent mixture and efficient grinding, the materials may be in the form of chunks, granules, or powders.

Once the materials are loaded, the ball mill goes to work. The key component responsible for the grinding action is the “grinding media,” typically in the form of balls or spheres made from various materials such as steel, ceramic, or even glass. As the mill rotates, these balls tumble within the drum, subjecting the materials to both impact and attrition forces. The combination of these forces effectively breaks down the particles, reducing them in size.

After the desired grinding time, the milled material is typically discharged from the mill through one of several methods. This can include a discharge chute, a screen, or even a pump if the material is in a slurry form. The final product is a finely ground powder ready for further processing or use.

Ball mills are versatile machines, and their applications span across a wide range of industries. Some of the primary uses include:

The ball mill is a crucial piece of equipment in various industries, including mining, cement, and pharmaceuticals, among others. Its significance lies in its ability to grind materials into fine powders, making it an essential tool in the production process. However, when it comes to purchasing a ball mill, one must consider several factors that influence its price.

One of the primary factors influencing the price of a ball mill is its size and capacity. Ball mills come in various sizes, ranging from small laboratory-scale mills to large industrial units capable of handling substantial amounts of material. Naturally, larger and higher-capacity ball mills tend to be more expensive than their smaller counterparts.

The size and capacity of a ball mill directly affect its production efficiency and throughput. Businesses that require high-volume grinding will need to invest in larger mills, which typically come at a premium cost. Smaller mills, on the other hand, are more suitable for research or small-scale production, making them a cost-effective choice for certain applications.

The materials used in the construction of a ball mill play a significant role in determining its price. High-quality materials and precision engineering contribute to better performance, durability, and longevity, which can justify a higher price tag. Ball mills are typically constructed using materials like stainless steel, ceramic, or high-quality alloy steel.

Stainless steel mills are known for their corrosion resistance and suitability for applications involving corrosive materials. Ceramic mills, on the other hand, are often preferred for their wear resistance, especially when processing abrasive substances. The choice of construction materials should align with the specific requirements of the industry or process in which the ball mill will be used.

Brand reputation and reliability are vital factors in the pricing of ball mills. Established and reputable manufacturers often charge a premium for their products due to the trust and confidence they have earned in the market. These manufacturers have a track record of producing high-quality, reliable ball mills that meet industry standards and customer expectations.

When purchasing a ball mill, buyers must consider the manufacturer’s reputation for producing machines that require minimal maintenance and offer consistent performance over time. The reliability of a ball mill is crucial to avoid costly downtime and repairs, making it a worthwhile investment for businesses that prioritize efficiency and productivity.

The principles of supply and demand exert a significant influence on ball mill prices. When there is a high demand for ball mills in the market and limited supply, prices tend to rise. Conversely, when demand is low or there is an oversupply of ball mills, prices may decrease. Market conditions, including economic trends and industry-specific factors, can impact the pricing dynamics of ball mills.

Market demand can also be influenced by technological advancements and industry trends. For instance, as industries evolve and require more sophisticated milling equipment, the demand for advanced ball mills with specialized features may increase, leading to higher prices for such specialized models.

The geographic location of the buyer can also affect the price of ball mills. Shipping costs, import/export tariffs, and taxes can vary significantly depending on the destination. To illustrate this point, let’s consider Thailand as a case study.

Thailand, a Southeast Asian country with a growing industrial sector, is a major player in the region’s manufacturing and processing industries. Businesses in Thailand that require ball mills may enjoy cost advantages when purchasing from domestic manufacturers due to reduced shipping costs and lower import tariffs compared to importing from overseas suppliers.

However, the geographic location can also present challenges. For instance, if a specific type or size of ball mill is not readily available in Thailand, businesses may need to import it, incurring higher costs associated with international shipping and customs duties.

The ball mill is a crucial piece of machinery used in various industries, including mining, construction, and ceramics, for grinding materials into fine powder. In the Thai market, as in many other countries, the price of ball mills fluctuates due to a variety of factors.

Ball mill prices in the Thai market have experienced fluctuations in recent years. These fluctuations can be attributed to several factors, including changes in demand, supply chain disruptions, and currency exchange rates. As of the most recent data available, the price range for ball mills in Thailand varies widely, depending on factors such as size, capacity, and specifications. Small laboratory-scale ball mills may be available for as low as 50,000 Thai Baht (approximately $1,500 USD), while larger industrial-grade ball mills can reach prices exceeding 2 million Thai Baht (approximately $60,000 USD).

It’s essential to note that these prices are indicative and can change rapidly due to market dynamics. Buyers interested in purchasing a ball mill should closely monitor the market and conduct thorough research to find the best value for their specific requirements.

Several economic and industrial factors in Thailand can influence ball mill prices. Understanding these factors is crucial for both buyers and suppliers in the market.

Thailand’s overall economic growth plays a significant role in determining the affordability of industrial machinery like ball mills. During periods of robust economic growth, businesses are more likely to invest in equipment, potentially driving up demand and prices.

Exchange rates can affect the cost of imported components and machinery used in the manufacturing of ball mills. A weaker Thai Baht can lead to higher costs for imported materials, which may be passed on to consumers in the form of higher prices.

The prices of raw materials such as steel, which is commonly used in the construction of ball mills, can fluctuate due to global market conditions and supply chain disruptions. These fluctuations can directly impact the manufacturing costs of ball mills.

The level of competition among ball mill manufacturers and suppliers in Thailand can influence pricing. A highly competitive market may lead to more competitive prices as manufacturers strive to attract customers.

Regulations and Import Taxes:

Government regulations and import taxes can also affect the final price of ball mills. Import taxes on certain components or machinery can increase production costs and, subsequently, the price of the final product.

To provide a more comprehensive view of ball mill prices in the Thai market, we will conduct a comparative analysis of prices from different suppliers or manufacturers. Keep in mind that these prices are for illustrative purposes and may vary based on specifications and negotiations.

Supplier A offers a range of ball mills suitable for laboratory and small-scale industrial applications. Their prices start at 50,000 Thai Baht for basic models with smaller capacities and go up to 300,000 Thai Baht for larger, more advanced models. Supplier A is known for its competitive pricing and reliable customer support.

Supplier B specializes in high-capacity industrial ball mills for large-scale manufacturing operations. Their prices are significantly higher, starting at 1.5 million Thai Baht for entry-level industrial models and reaching 3 million Thai Baht for advanced systems with additional features and automation. Supplier B is renowned for the durability and performance of its products.

Supplier C focuses on mid-range ball mills suitable for various industrial applications. Their prices fall between those of Supplier A and Supplier B, starting at 300,000 Thai Baht for standard models and going up to 1 million Thai Baht for more specialized versions. Supplier C prides itself on offering a balance between quality and affordability.

When it comes to materials processing and particle size reduction, few pieces of equipment are as versatile and essential as the ball mill. Whether you’re in the pharmaceutical, mining, ceramics, or chemical industry, selecting the right ball mill can significantly impact your productivity and product quality. With various models and options available, finding the perfect fit can be a daunting task.

Before diving into the world of ball mills, it’s crucial to evaluate your specific needs and objectives. Here are some key factors to consider:

The type of material you intend to process plays a fundamental role in determining the type of ball mill you need. Different materials, such as metals, minerals, ceramics, or pharmaceutical compounds, have varying characteristics and require specific milling equipment. For example, fragile materials like ceramics may require a gentler approach, while metals might demand more robust milling machinery.

What is the target particle size distribution you need to achieve? Some applications require fine powders, while others may need coarse particles. The milling process and the type of mill you choose will greatly impact your ability to achieve the desired particle size.

Consider the volume of material you need to process per unit of time. This will determine the required capacity of the ball mill. If you have high-volume production needs, you’ll need a larger mill with higher throughput capabilities.

Decide whether you need batch processing or continuous operation. Batch mills are suitable for small-scale production and experimentation, while continuous mills are ideal for large-scale, continuous production.

Establish a clear budget for your ball mill purchase. The cost of ball mills can vary significantly based on factors such as size, capacity, and features. Having a budget in mind will help you narrow down your options and make a more informed decision.

Once you’ve assessed your requirements, it’s time to delve deeper into the factors that will influence your decision when purchasing a ball mill.

1. Type of Ball Mill: There are several types of ball mills available, including:

Choose the type that aligns with your material and processing requirements.

s. This not only fosters positive relationships with local communities but also aligns with global ESG (Environmental, Social, and Governance) standards, attracting socially conscious investors.

Our Projects

Copyright © ZENITH, All Right Reserved.