The applications of 150 TPH mobile stone crushers in construction are diverse and far-reaching. From road building and high-rise construction to landscaping and remote projects in developing nations, these machines have proven to be indispensable tools for modern construction professionals.

24 Online Service

In the ever-evolving world of construction and infrastructure development, the demand for efficient machinery to crush and process stone materials is on the rise. One of the most significant developments in this domain is the advent of mobile stone crushers. These versatile machines have revolutionized the way construction and mining industries approach stone crushing.

Mobile stone crushers are portable crushing machines designed to process and crush a variety of stone materials on-site. Unlike traditional stationary stone crushers, mobile crushers can be transported to different locations, making them highly versatile and suitable for a wide range of construction projects, from road construction and building sites to mining operations. These crushers are particularly beneficial in remote or temporary construction sites, where the transportation of raw materials to a fixed crushing unit would be impractical or costly.

The market offers a diverse range of mobile stone crushers to cater to the specific needs of various construction and mining projects. Among these, the 150 TPH mobile stone crusher is a popular choice for mid-sized to large-scale projects, striking a balance between portability and crushing capacity. Let’s explore some of the different types and models available:

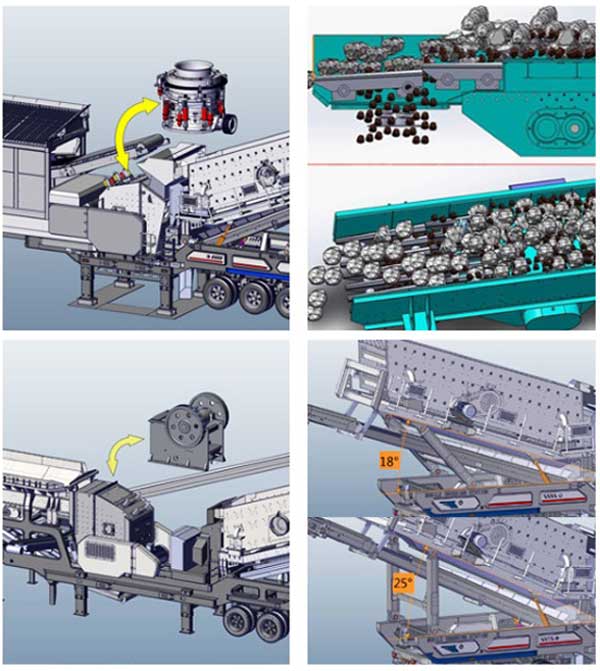

These mobile crushers use a fixed jaw and a moving jaw to crush the stone. They are well-suited for a wide range of materials, including hard and abrasive ones. Jaw crushers can handle large pieces of rock and produce fine to coarse aggregate.

Mobile cone crushers are designed for secondary and tertiary crushing. They are highly efficient at producing well-shaped, cubic final products. Cone crushers are ideal for processing medium to hard stone materials.

These crushers use hammers or blow bars to impact the stone and break it into smaller pieces. They are known for their high reduction ratio and are suitable for processing materials with lower abrasiveness.

Among the various options, the 150 TPH mobile stone crusher stands out for its balanced performance. It can efficiently process a wide range of stone materials and offers a high level of mobility, making it suitable for both temporary and long-term construction projects. Its moderate capacity makes it ideal for a variety of applications, including road construction, building construction, and mining operations.

The 150 TPH mobile stone crusher is equipped with several key features and components that make it an excellent choice for construction projects:

The mobile crusher is mounted on a wheeled chassis, which allows it to be easily transported from one site to another. This mobility is crucial for projects that require crushing at multiple locations.

It incorporates a highly efficient crushing system with a primary jaw crusher or cone crusher, depending on the model. This system ensures the production of high-quality aggregates for various construction purposes.

These crushers are designed for easy maintenance, with readily accessible components and minimal downtime, ensuring that the machine remains operational for extended periods.

Many mobile crushers come with remote control features, allowing operators to adjust settings and monitor the machine’s performance from a safe distance.

To enhance environmental safety and reduce dust emissions, a dust suppression system is often integrated into the crusher.

These crushers can be powered by electricity or diesel, depending on the availability of energy sources at the construction site.

Some models include a scalping screen that separates finer materials, allowing for better control over the final product size.

These key features and components collectively make the 150 TPH mobile stone crusher a versatile and reliable machine for various construction projects.

Understanding how mobile stone crushers operate and process raw materials is essential to appreciate their significance in construction and mining. The working mechanism of these crushers can be broken down into several stages:

The first step in the process involves the loading of raw materials onto the mobile crusher’s feed hopper. Depending on the type of stone and the crusher’s configuration, a front-end loader or an excavator may be used for this purpose.

Once the raw materials are loaded, the crusher’s primary crushing unit, which can be a jaw crusher or a cone crusher, begins to break down the stone into smaller pieces. The stone is fed into the crushing chamber, where the mobile crusher exerts significant force to crush and reduce it.

After the initial crushing, the crushed stone is conveyed to the secondary and tertiary crushers, if applicable. In the case of a cone crusher, it may go through additional crushing stages. Conveyors and belts transport the material between different units of the crusher.

Some mobile crushers include a screening unit that separates the desired-sized aggregates from the smaller ones. This step is crucial in controlling the quality of the final product, as it ensures that only properly sized materials are used for construction purposes.

The crushed and screened stone is then collected as the final product, ready for use in construction projects. The quality and gradation of the final product can be controlled by adjusting the crusher settings and the screening process.

One of the pivotal innovations in recent years is the development and deployment of 150 TPH mobile stone crushers. These versatile machines have become indispensable tools in various construction projects, from road building to building construction and landscaping.

One of the most significant applications of 150 TPH mobile stone crushers is in road construction. Roads are essential for the efficient transportation of goods and people, and these crushers play a crucial role in building and maintaining them. The primary function of mobile stone crushers in road construction is to break down large rocks, stones, and boulders into smaller, more manageable materials for use in various layers of road construction.

The expansion of Interstate 10 is a prime example of the crucial role played by mobile stone crushers in road construction. To accommodate increased traffic, a wider and more robust road was required. Mobile stone crushers were used to crush large rocks and boulders, producing the necessary materials for constructing a more extensive and safer roadway. This project showcased the efficiency and versatility of mobile stone crushers in tackling large-scale road construction.

In building construction, mobile stone crushers are utilized for a variety of purposes. They aid in the preparation of building sites, clearing away debris and unwanted materials, and crushing rocks to produce the necessary materials for various construction phases. These crushers ensure that construction materials are readily available and can be tailored to specific project requirements.

High-rise construction in densely populated urban environments often faces space constraints and logistical challenges. Mobile stone crushers played a pivotal role in a high-rise construction project in a major city. These crushers efficiently processed on-site materials, reducing the need for transporting large volumes of materials through congested city streets. The on-site production of construction materials not only saved time but also reduced the project’s environmental footprint.

Landscaping projects, whether for residential or commercial purposes, require the efficient processing of materials such as rocks, stones, and gravel. Mobile stone crushers are versatile tools for landscaping professionals. They can crush and process materials to create custom landscapes, retaining walls, pathways, and decorative elements.

In the creation of a picturesque garden for a high-end residential project, mobile stone crushers were used to process a variety of materials. Large rocks were crushed to produce decorative pebbles and gravel for pathways and water features. The crushers’ mobility allowed them to be easily relocated within the project site, ensuring efficient material processing at different stages of the landscaping project. The end result was a beautifully landscaped garden that added significant value to the property.

A quarry in Europe embarked on an expansion project to meet the growing demand for construction aggregates. They chose to employ a 150 TPH mobile stone crusher to process the extracted rocks and produce various grades of aggregates. This decision greatly increased the quarry’s production capacity while also reducing the cost of transporting materials to customers. The mobile stone crusher’s mobility and versatility made it the ideal choice for this project, resulting in improved efficiency and profitability for the quarry.

In remote construction projects in developing nations, access to conventional construction materials can be limited. In one such project, a mobile stone crusher was used to process local rocks and stones to build infrastructure in a remote village. This not only reduced the project’s reliance on costly imported materials but also created employment opportunities for local residents. The mobile stone crusher’s compact design and mobility proved indispensable in reaching remote locations, making this project a success story in sustainable and community-focused construction.

Urban redevelopment projects in densely populated Asian cities often require the demolition of existing structures and the recycling of construction materials. In a major urban redevelopment project, a 150 TPH mobile stone crusher played a dual role. It was used to process the debris from demolished buildings and to produce recycled materials for the construction of new structures. The crushers’ ability to handle diverse materials and the reduced need for transporting materials off-site contributed to the project’s overall efficiency and sustainability.

Our Projects

Copyright © ZENITH, All Right Reserved.