Copper ore processing plants are shaping the pricing dynamics of copper. Efficiency and technological advancements in these plants are instrumental in determining the overall cost of copper production. As the industry continues to evolve, embracing automation, data analytics, and sustainable practices, the influence of processing plants on copper prices will likely intensify.

24 Online Service

The journey from raw copper ore to the refined metal involves a complex and intricate process known as copper ore processing.

The journey of copper begins deep beneath the Earth’s surface in mines rich with copper ore deposits. Mining is the initial step in the copper production process, and it involves extracting the ore from the earth. Traditional mining methods include open-pit mining, underground mining, and heap leaching, each chosen based on the ore’s grade, depth, and location. These methods aim to maximize the extraction of copper-rich ore while minimizing environmental impact.

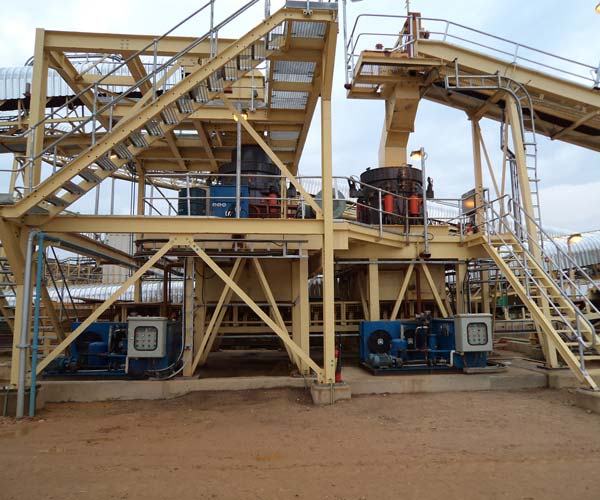

Once the ore is extracted, it undergoes a series of processes to prepare it for further refinement. The extracted ore is typically a mixture of copper minerals and gangue minerals, which need to be separated. The first stage in this separation process is crushing and grinding. Massive chunks of ore are broken down into smaller pieces through crushers and grinders, reducing the ore to a size suitable for subsequent stages.

With the ore reduced to a manageable size, the next critical step is flotation. Flotation is a selective separation process that exploits the differences in the surface chemistry of minerals. In this stage, the crushed and ground ore is mixed with water and chemicals to create a slurry. Air bubbles are then introduced, causing the copper minerals to attach to the bubbles and rise to the surface, forming a froth. The froth, rich in copper concentrate, is skimmed off and further processed, leaving behind the unwanted gangue minerals.

The copper concentrate obtained from flotation contains a high percentage of copper but still requires further refinement to become the pure, market-ready metal. Smelting is the pivotal stage in this transformation. In a smelter, the copper concentrate is heated to high temperatures, typically over 1,000 degrees Celsius, in the presence of oxygen and fluxes. This process melts the concentrate, separating the copper from impurities and forming a molten copper matte.

During smelting, additional reactions take place to remove sulfur and iron from the molten copper, ensuring the final product meets the desired purity levels. The resulting liquid copper is then cast into anodes, which serve as the raw material for the final refining stages.

To achieve the highest purity levels, the copper anodes undergo electrorefining, the last stage in the copper production process. Electrorefining takes place in electrolytic cells filled with an electrolyte solution containing copper sulfate. When an electric current is applied, copper ions from the anodes migrate to the cathode, where they are deposited as pure copper metal. This process eliminates remaining impurities, resulting in a high-quality copper cathode ready for market.

Efficient copper ore processing is imperative for ensuring cost-effective copper production. The mining, crushing, grinding, flotation, and smelting stages demand significant energy and resources. Any inefficiency in these processes not only hampers production but also contributes to increased costs and environmental impact.

Efficiency in copper processing can be achieved through technological advancements, process optimization, and sustainable practices. Innovations in mining equipment, crushing, and grinding technologies can enhance the extraction of copper ore while minimizing energy consumption. Additionally, advancements in flotation techniques and smelting technologies contribute to higher recovery rates and reduced environmental impact.

Cost-effectiveness in copper processing also involves waste management and environmental responsibility. Utilizing sustainable mining practices, recycling process water, and minimizing emissions during smelting contribute to a more environmentally friendly and economically viable copper production.

At the heart of this process lie Copper Ore Processing Plants, where technological advancements play a pivotal role in determining the overall cost of copper production.

Efficiency is the linchpin of copper ore processing plants, directly influencing production costs. These plants undertake a series of complex steps to extract copper from ore, and any improvement in efficiency can significantly impact the final price of the metal.

The initial step involves extracting copper from ore through processes like crushing, grinding, and flotation. Innovations in these processes can enhance extraction rates, reducing the amount of raw ore needed for production. Advanced machinery and techniques streamline operations, contributing to increased efficiency.

>

Energy-intensive processes are intrinsic to copper extraction. Technological advancements that reduce energy consumption are not only environmentally sustainable but also economically beneficial. Utilizing renewable energy sources or implementing energy-efficient equipment can curtail operational costs, positively influencing the overall price of copper.

The evolution of technology has brought about transformative changes in copper ore processing. Cutting-edge advancements have enabled more precise and resource-efficient methods, ultimately impacting the economics of copper production.

Automation is revolutionizing copper processing plants. Automated systems not only enhance operational efficiency but also reduce the margin for error. From autonomous trucks transporting ore within the plant to automated control systems optimizing the extraction process, these innovations streamline operations, minimizing costs.

The integration of data analytics and artificial intelligence (AI) in copper processing plants allows for real-time monitoring and decision-making. Predictive maintenance powered by AI can prevent costly breakdowns, while data analytics optimize the entire production process. These technologies contribute to a more agile and responsive operation, ultimately influencing the price of copper.

Modern copper ore processing plants are increasingly adopting environmentally sustainable practices. From water recycling to minimizing emissions, these practices not only align with global sustainability goals but also often lead to cost savings. Sustainable copper production is becoming a crucial factor for buyers, shaping market demand and subsequently influencing prices.

The intersection of efficiency and technological innovation in copper ore processing plants has a profound impact on the pricing dynamics of copper.

Improved efficiency and technological innovations directly translate into cost reductions. As the cost of extraction and processing decreases, copper producers can maintain profitability even in the face of fluctuating market prices. This resilience contributes to price stability in the copper market.

Copper producers equipped with advanced processing technologies gain a competitive edge in the market. In a global economy where buyers seek not only quality but also sustainable and cost-effective products, technologically advanced processing plants can attract more customers, further influencing market prices.

The efficiency of copper processing plants also affects the overall supply of copper in the market. A well-optimized production process ensures a steady supply of copper, preventing shortages that could drive prices up. Conversely, an oversupply resulting from inefficient processing can lead to a price decrease.

The mining industry plays a pivotal role in the global economy, with copper being one of the most sought-after metals due to its extensive applications in various sectors. In the pursuit of extracting copper from ore, processing plants face numerous challenges, including cost management and operational efficiency.

The Escondida Copper Mine, located in the Atacama Desert of Chile, stands as the world’s largest copper-producing mine. Its success is attributed not only to its vast copper reserves but also to its innovative and strategic approach to ore processing.

Escondida employs advanced technologies, such as heap leaching and solvent extraction-electrowinning (SX-EW), to optimize the cost-effectiveness of copper extraction. Heap leaching involves stacking ore in heaps and irrigating it with a leaching solution, minimizing infrastructure costs. The SX-EW process is employed for low-grade ores, enhancing efficiency by directly producing copper cathodes.

Escondida maximizes operational efficiency through continuous monitoring and automation. Advanced sensors and control systems are integrated into the processing plant, allowing real-time data analysis and process optimization. This not only reduces manual intervention but also enhances overall efficiency, ensuring a steady and reliable copper production process.

Situated in the South Gobi Desert, the Oyu Tolgoi Mine is a significant copper and gold mining complex. This operation has gained acclaim for its commitment to sustainability and its innovative approach to ore processing.

To enhance operational efficiency, Oyu Tolgoi employs state-of-the-art flotation technologies in its ore processing plant. These technologies enable the extraction of a higher percentage of copper from ore, maximizing the yield. Additionally, the mine invests in employee training programs to ensure a skilled workforce capable of optimizing plant operations.

The Collahuasi Mine, located in northern Chile, is a joint venture between Anglo American, Glencore, and Mitsui. Recognized for its commitment to environmental responsibility, Collahuasi serves as a benchmark for sustainable copper ore processing.

Collahuasi embraces a circular economy approach, where waste generated during the mining process is recycled or repurposed. This not only minimizes waste disposal costs but also contributes to the responsible use of resources. The mine also invests in predictive maintenance technologies, reducing downtime and maintenance-related expenses.

To enhance operational efficiency, Collahuasi implements comprehensive water management strategies. Given Chile’s arid climate, water scarcity is a significant concern. Collahuasi employs cutting-edge technologies for water recycling and conservation, ensuring optimal water usage in the ore processing plant. This not only addresses environmental concerns but also contributes to cost savings by reducing water consumption.

The Batu Hijau Mine, situated on the Indonesian island of Sumbawa, is known for its large copper and gold reserves. This mine’s success is underpinned by its innovative approach to ore processing and commitment to community engagement.

In terms of operational efficiency, Batu Hijau utilizes cutting-edge grinding and flotation technologies. These advancements enable the mine to process larger volumes of ore with higher copper concentrations, significantly increasing overall efficiency. Moreover, the mine prioritizes employee well-being through safety training and health programs, ensuring a motivated and productive workforce.

Our Projects

Copyright © ZENITH, All Right Reserved.