Cheapest ballast crushers have transformed the landscape of ballast production in Kenya. Through their cost advantages, portability, and environmental friendliness, these crushers have overcome the limitations of traditional options, making them integral to railway development projects.

24 Online Service

Among the various modes of transportation, railways have stood the test of time as an efficient and reliable means of transport. One often overlooked yet essential component of railway tracks is ballast, a seemingly humble material that plays a crucial role in the overall functionality and longevity of the railway network.

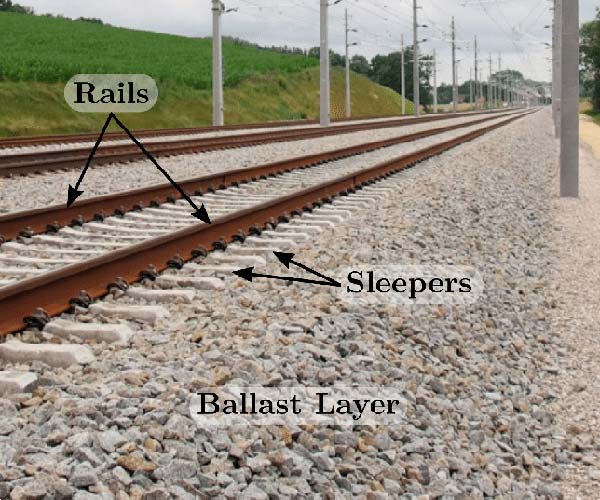

In the context of railways, ballast refers to the layer of coarse, angular stones that is placed beneath and around the sleepers (or ties) and railway tracks. This layer serves as a foundation, distributing the load of the train and ensuring the stability of the tracks. Ballast also serves to provide effective drainage, preventing water accumulation that could lead to erosion and weakening of the track structure.

The primary function of ballast is to provide stability to the railway tracks. Trains exert immense forces on the tracks due to their weight and speed. Without proper stability, tracks could shift, warp, or even buckle under the pressure. Ballast acts as a buffer between the sleepers and the underlying soil. Its irregular shape and interlocking nature create a stable platform that distributes the load of the trains evenly, preventing excessive stress on any one point. This stability not only ensures a smooth ride for passengers and cargo but also reduces the need for frequent maintenance and repairs.

Railway tracks are exposed to various weather conditions, and the accumulation of water can be detrimental to their integrity. Here is where ballast plays a critical role. The voids between the ballast stones allow water to drain away from the tracks efficiently, preventing waterlogging and the formation of soft spots that could compromise the track’s stability. Effective drainage facilitated by ballast helps in maintaining the structural integrity of the trackbed, reducing the likelihood of erosion and subsidence.

The concept of weight distribution is paramount in the design and operation of railway tracks. As a train passes over the tracks, the weight is transmitted through the wheels to the rails and then to the ballast. The ballast, in turn, distributes this weight evenly across the trackbed and the underlying soil. Proper weight distribution prevents excessive pressure on any specific point and minimizes the risk of track deformations. By allowing the load to be spread out, ballast contributes to the longevity of the tracks and minimizes the need for frequent repairs.

In an era of growing infrastructure demands and constrained budgets, cost-effectiveness is a critical consideration in railway projects. While the role of ballast is indispensable, it’s equally important to explore cost-effective solutions that ensure efficient track performance without unnecessary expenditures.

One approach is the utilization of alternative ballast materials. Traditionally, crushed stone has been the primary choice for ballast due to its durability and availability. However, the extraction, transportation, and placement of natural stone can incur significant costs. Exploring alternative materials, such as recycled aggregates or synthetic materials, can present more economical options without compromising track performance. These alternatives can not only reduce expenses but also contribute to sustainability by reusing materials that might otherwise end up as waste.

Furthermore, advancements in technology and engineering have led to innovative track designs that optimize ballast usage. The use of geosynthetic materials, like geotextiles and geogrids, can enhance the load-bearing capacity of the trackbed while reducing the amount of ballast required. These materials improve the overall stability and longevity of the track system, thereby reducing maintenance and replacement costs in the long run.

Ballast, an essential component of railway tracks, may seem inconspicuous at first glance, but it plays a crucial role in ensuring the safety, stability, and longevity of the rail network. This unassuming material, typically made from stones and gravel, forms the foundation upon which trains traverse thousands of miles, carrying people and goods to their destinations. However, the process of producing quality ballast is far from simple, and it is here that crushers step in, breaking down large raw materials into smaller, usable sizes that are integral to the ballast production process.

Before exploring the significance of crushers in ballast production, it’s important to understand the journey of raw materials to the robust tracks we see today. Ballast is composed of various materials, predominantly crushed stones and gravel. These materials are carefully selected for their durability, strength, and ability to withstand the immense pressures exerted by passing trains.

The production of high-quality ballast begins with the extraction of suitable raw materials from quarries. Large rocks are hauled from quarries to crushing plants, where they undergo a series of crushing and screening processes to create the desired sizes and specifications. Traditionally, manual labor was extensively employed for this purpose, but modern technology has revolutionized the process, leading to increased efficiency and productivity.

At the heart of ballast production lies a technological marvel: crushers. These machines are designed to break down large rocks and stones into smaller, more manageable sizes, which are then used to create the foundation of railway tracks. Crushers come in various types, each tailored to specific materials and production needs. Among the common types are jaw crushers, impact crushers, and cone crushers, each uniquely suited to different stages of the crushing process.

The role of crushers in ballast production cannot be overstated. They form the linchpin of the process, ensuring that raw materials are transformed into consistent, high-quality ballast that meets the rigorous demands of the railway industry. Here’s why crushers are indispensable:

Raw materials extracted from quarries are often too large to be directly used as ballast. Crushers play a pivotal role in reducing these large rocks into smaller, uniform sizes, which are easier to handle and transport.

Ballast needs to have consistent properties to provide stable support to the tracks. Crushers ensure uniformity in size and quality, resulting in ballast that is evenly distributed and able to withstand the pressures of heavy train traffic.

Crushers enable efficient use of raw materials by reducing wastage and maximizing the yield of usable ballast. This not only saves resources but also contributes to the sustainability of the rail infrastructure.

Different crushers offer the flexibility to create various sizes of ballast tailored to specific project requirements. This adaptability is essential for accommodating diverse track configurations and load-bearing capacities.

The quality of ballast directly impacts the longevity of railway tracks. Properly crushed ballast provides a solid foundation that minimizes track deterioration and maintenance needs, ultimately reducing costs and downtime.

The process of crushing involves several stages, each aimed at progressively reducing the size of the raw materials. In the primary crushing stage, large rocks are fed into the crusher’s chamber, where they are subjected to the force of moving surfaces. Jaw crushers, for instance, use a fixed plate and a moving plate to crush the rocks between them.

Impact crushers, on the other hand, use the principle of rapid impact to shatter materials. The feed material is propelled into the impact chamber, where it collides with rapidly rotating hammers or blow bars. This impact results in the fragmentation of the material into smaller pieces.

Cone crushers, with their conical shape, are particularly suited for secondary and tertiary crushing. The material is fed into the top of the cone-shaped chamber and is gradually compressed and crushed as it moves towards the bottom, where the final product emerges.

Kenya’s railway network is the backbone of the country’s transportation infrastructure, connecting major cities and fostering economic growth. However, the maintenance and development of this network heavily rely on the availability of high-quality ballast, the gravel-like material that supports and stabilizes the tracks. With the aim to make ballast production cost-effective and environmentally sustainable, Kenya has witnessed the emergence of affordable ballast crushers that have revolutionized the industry.

In the past, ballast production in Kenya faced numerous challenges, including high costs and environmental concerns. Traditional crushers were expensive to operate and often emitted excessive dust, leading to environmental degradation and health hazards for nearby communities. These issues not only hindered sustainable railway development but also burdened project budgets and timelines.

The turning point came with the introduction of affordable ballast crushers that combined advanced technology with affordability. These crushers offered a solution to the cost and environmental challenges, enabling railway projects to progress smoothly while adhering to budget constraints and ecological regulations.

One prominent example is the Zenith Ballast Crushers, a company that has been at the forefront of producing affordable and environmentally friendly ballast crushing machines. Their machines have been game-changers in the industry. Equipped with diesel engines, these crushers can be easily transported to various construction sites, making them suitable for both large-scale railway projects and smaller endeavors.

The success of affordable ballast crushers hinges on their unique features that set them apart from traditional crushers. Some of the key advantages include:

The primary advantage of these crushers is their lower cost of ownership and operation. They are designed with simplicity in mind, reducing the complexity of maintenance and repairs. This not only lowers initial investment but also ensures that ongoing operational costs remain manageable.

Many affordable ballast crushers are portable, allowing them to be moved to different locations as needed. This flexibility is essential for tackling projects in remote areas or regions with limited infrastructure.

These crushers are designed to maximize efficiency in ballast production. They crush rocks into the optimal size required for ballast, minimizing waste and ensuring that the produced material meets the necessary specifications for railway construction.

Modern affordable ballast crushers prioritize environmental sustainability. They are equipped with dust suppression systems that control airborne particles, reducing the impact on air quality and surrounding ecosystems. This advancement addresses the concerns raised by communities living near construction sites.

The cost advantages of affordable ballast crushers are evident across various aspects:

Traditional crushers often require a substantial initial investment, including high installation costs and specialized infrastructure. Affordable ballast crushers, on the other hand, are designed to be more budget-friendly, making them accessible to a broader range of projects and investors.

The simplicity of design and reduced complexity of affordable crushers translate into lower operational expenses. They consume less fuel, require less frequent maintenance, and have longer service lives, ultimately leading to decreased operating costs.

Railway projects are time-sensitive endeavors, and any delays can have significant financial implications. Affordable ballast crushers are known for their quick setup and efficient crushing processes, contributing to faster project completion and reduced downtime.

The impact of affordable ballast crushers on railway projects in Kenya is evident through success stories that highlight their contribution to sustainable development. For instance, the use of these crushers in the construction of the Standard Gauge Railway (SGR) project played a pivotal role in meeting the project’s ballast needs within budget and schedule constraints.

The SGR, a landmark infrastructure project, required vast quantities of ballast for its tracks. By employing affordable ballast crushers, the project managed to keep costs under control while adhering to high-quality standards. The crushers’ efficiency ensured a consistent supply of quality ballast, supporting the project’s overall progress and contributing to the growth of the nation’s economy.

Our Projects

Copyright © ZENITH, All Right Reserved.