In the grand tapestry of industrial processes, the role of ball mill grinders is undoubtedly significant. Their ability to produce fine and uniform particles, facilitate blending and mixing, and operate with exceptional energy efficiency sets them apart as indispensable tools across various industries. From enhancing product quality to reducing operational costs and environmental impact, ball mills have redefined the standards of grinding technology.

24 Online Service

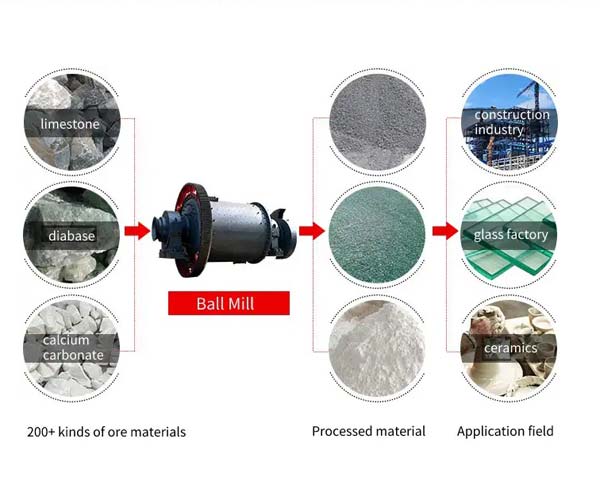

In the realm of industrial processes for transforming raw materials into valuable products, the ball mill grinder stands as an essential tool. Its intricate design and operational principles have allowed it to become a staple in various manufacturing and materials processing industries. From minerals to paints, pyrotechnics to ceramics, the ball mill grinder is a ubiquitous sight, responsible for performing the vital task of reducing materials to a finer consistency.

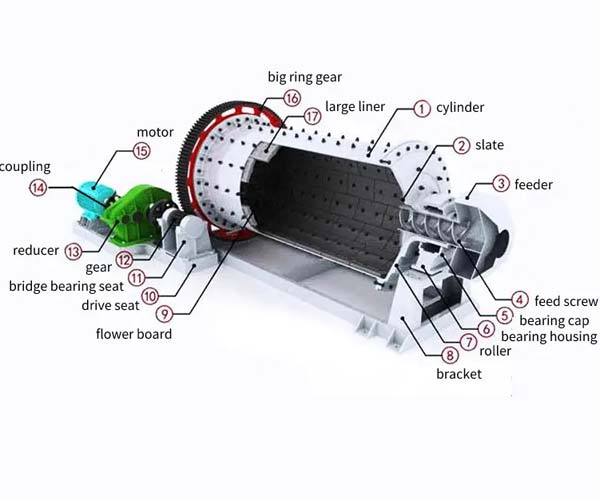

At its heart, a ball mill grinder comprises a cylindrical vessel that rotates around its axis. This vessel, often referred to as the mill, houses a multitude of steel or ceramic balls that serve as the grinding media. The material to be ground, ranging from coarse chunks to finely powdered substances, enters the mill either through a feed chute or a charging port. As the mill rotates, the grinding media cascade and collide within the cylindrical space, gradually fragmenting the raw material into smaller particles.

The central component of the ball mill grinder is the cylindrical vessel, which is typically made of steel, though it can also be constructed from ceramic materials. This vessel is mounted horizontally and is either partially filled or loaded with the material to be ground.

The grinding media, usually spherical in shape and ranging from a few millimeters to several centimeters in diameter, occupy a significant volume within the mill. As the cylinder rotates, these balls are lifted to a certain height and then allowed to fall, creating impacts and frictional forces that lead to the breakdown of the material.

The material subjected to grinding is introduced into the mill through the feed chute or charging port. This could be anything from minerals like limestone and quartz to pigment compounds used in paints.

The efficacy of the ball mill grinder hinges on the interplay between the grinding media and the material being ground. This interaction is primarily governed by two forces: impact and attrition.

As the mill rotates, the grinding media are lifted to a certain height before gravity pulls them down, causing them to collide with the material within the cylinder. These collisions generate significant impact forces, leading to the fragmentation of the material into smaller particles. The kinetic energy transferred during these impacts is crucial for reducing the material’s size.

In addition to impacts, the grinding media also exert a rubbing or attrition force on the material. This force arises from the movement of the balls against the particles, resulting in their gradual reduction in size through repeated abrasion and wear.

Ball mill grinders come in a variety of configurations, each tailored to specific applications and operational requirements. Some of the notable variations include:

Dry ball mills operate without any moisture, making them suitable for applications where dry materials need to be ground. They are commonly used in cement production and certain types of mineral processing.

Wet ball mills incorporate water or other liquids into the grinding process. These mills are advantageous for reducing material viscosity and preventing undesirable reactions. They find use in industries such as ceramics and chemical processing.

Batch ball mills are designed to process a finite amount of material at a time. Once the material is ground to the desired size, the mill is emptied, and the next batch can be introduced. These mills are often used for small-scale production or laboratory testing.

Continuous ball mills maintain a continuous feed of material, ensuring a steady output without the need for frequent stops and starts. They are commonly employed in large-scale manufacturing operations.

India’s industrial landscape is a diverse and dynamic realm, spanning a multitude of sectors that contribute significantly to its economic growth. Among the many tools powering these industries, the ball mill grinder stands out as a crucial instrument in achieving efficient grinding processes. From cement and mining to pharmaceuticals and ceramics, the applications of ball mill grinders are pervasive, playing a pivotal role in shaping the production landscape and bolstering the Indian economy.

The cement industry in India is a cornerstone of the country’s infrastructure development. A key stage in cement manufacturing involves the comminution of raw materials into a fine powder, a process integral to the quality and strength of the final product. This is where ball mill grinders come into play. These grinders meticulously reduce the raw materials, such as limestone and clay, to a fine powder, enhancing the reactivity and homogeneity of the mixture. The powdered blend is then subjected to high-temperature kilns, transforming it into clinker, the fundamental ingredient in cement production.

Without efficient grinding facilitated by ball mill grinders, the entire cement production process would be compromised. The durability of infrastructure, the growth of the construction sector, and consequently, the economic progress of India would be severely hindered.

The mining industry is another arena where ball mill grinders have etched their mark. India is endowed with a rich repository of minerals, ranging from coal and iron ore to precious metals and minerals. To extract these valuable resources from the earth’s crust, mining companies rely on grinding processes to pulverize the mined ore into a finely ground state. This finely ground ore can then be separated to extract the desired minerals through processes like flotation and smelting.

For instance, in iron ore mining, ball mill grinders crush and grind the ore to a suitable size for liberation, where the iron content can be efficiently separated from gangue minerals. The refined iron ore serves as a crucial input for the iron and steel industry, which is a pivotal sector for India’s economic growth.

India is globally acclaimed for its pharmaceutical industry, supplying a substantial portion of the world’s generic drugs. Within this sector, ball mill grinders play a significant role in the production of pharmaceutical powders. Drug manufacturing often involves the reduction of active pharmaceutical ingredients (APIs) into fine powders to ensure proper mixing and effective dosage. Ball mill grinders offer the precision required to achieve particle sizes conducive to optimal drug formulation.

In the pharmaceutical industry, a minor variation in particle size can have profound implications for a drug’s efficacy and safety. Therefore, the role of ball mill grinders in ensuring uniform and controlled particle size reduction is paramount, directly impacting the quality and therapeutic potential of pharmaceutical products.

The ceramics industry is yet another domain where ball mill grinders have made their presence felt. Ceramics, encompassing tiles, sanitaryware, tableware, and more, require raw materials to be ground to precise specifications. This grinding process enhances the materials’ consistency, facilitates uniform mixing, and contributes to the final product’s strength and aesthetics.

In the manufacture of ceramic tiles, for example, finely ground raw materials are mixed with water to form a slurry. This slurry is then dried and fired to create the finished product. The size and distribution of particles achieved through ball mill grinding impact the tiles’ density, porosity, and overall quality.

From minerals to paints, from pharmaceuticals to ceramics, a myriad of materials require size reduction to transform them into usable products or ingredients. Among the arsenal of grinding equipment, ball mill grinders stand out for their exceptional performance, efficiency, and versatility.

One of the most significant advantages of ball mill grinders lies in their ability to produce finely ground particles. Traditional grinding methods often result in uneven particle sizes and particle distribution, which can compromise the quality of the final product. However, ball mills, through their innovative design, ensure that particles are ground down to a precise and uniform size.

The grinding mechanism in ball mills is based on impact and attrition. A ball mill consists of a rotating drum filled with grinding balls, all of which are responsible for the grinding process. As the drum rotates, the grinding balls collide with and crush the material into smaller particles. This collision process results in the production of fine and uniform particles, a critical factor in industries where particle size distribution dictates product performance.

Ball mill grinders not only excel in grinding but also play a pivotal role in material blending and mixing. Many industries require a homogenous blend of different raw materials to create a consistent and high-quality end product. Ball mills are uniquely equipped to facilitate this blending process due to their rotating design, which ensures that the grinding media and materials are constantly in motion. This motion enhances the mixing of materials, resulting in a thoroughly blended and uniform composition.

The advantages of ball mill grinders extend beyond their grinding and blending prowess. These machines are renowned for their remarkable energy efficiency, which translates into significant cost savings and contributes to environmental sustainability. Compared to traditional grinding methods, such as rod mills or hammer mills, ball mills consume less energy for the same amount of grinding work.

The energy efficiency of ball mills can be attributed to their low friction and efficient impact mechanisms. As the grinding balls cascade within the rotating drum, they create a highly effective grinding action without excessive heat generation. Additionally, modern ball mill designs incorporate features that optimize airflow, further reducing the energy required for particle size reduction.

In the realm of industrial processes, efficient grinding holds the key to unlocking enhanced productivity and superior product quality. One of the pivotal tools in achieving this is the ball mill grinder.

A renowned steel manufacturing plant in India was grappling with suboptimal grinding processes that led to inconsistent particle size distribution and increased energy consumption. This resulted in decreased product quality and higher operational costs.

The plant decided to implement a modern ball mill grinder with advanced automation and precise control mechanisms. Additionally, they optimized the grinding media configuration to enhance the grinding efficiency. Continuous monitoring and adjustments were made through real-time data analytics.

The implementation led to a significant reduction in energy consumption per ton of output. The consistent particle size distribution resulted in improved downstream processes, such as sintering and pelletization. This not only increased the overall productivity but also elevated the quality of the final steel products, positioning the company as a leader in the industry.

A prominent cement production unit in India was facing challenges in achieving the desired fineness of their cement products. This not only impacted the cement’s setting time but also the compressive strength of the final structures, thereby jeopardizing their market reputation.

By integrating a high-efficiency ball mill grinder, the company aimed to ensure a more controlled and fine grind of the cement clinker. Advanced separator systems were employed to achieve the targeted fineness. Additionally, an enhanced ball grading technique was adopted to minimize over-grinding.

The company observed a substantial improvement in the cement’s quality parameters. The optimized grinding process resulted in cement with consistent particle size distribution, leading to better setting times and enhanced compressive strength. This success translated into a broader customer base and increased market share.

A pharmaceutical manufacturing plant in India confronted challenges in producing uniformly sized drug particles for their formulations. Inconsistent particle size led to variations in dosages and dissolution rates, affecting the efficacy of their medicines.

The plant incorporated a ball mill grinder equipped with specialized ceramic grinding media to achieve the desired particle size reduction. Tight control over the milling parameters, such as speed, time, and feed rate, was established. Moreover, stringent quality control protocols were implemented to ensure batch-to-batch consistency.

The utilization of ball mill grinders resulted in a precise and uniform particle size reduction, addressing the pharmaceutical company’s formulation challenges. This led to improved medication efficacy, as dosages became more predictable and dissolution rates were consistent. Consequently, the company gained a competitive edge by delivering more reliable pharmaceutical products to the market.

A well-established ceramic tile manufacturer in India was grappling with subpar glaze quality due to uneven particle size distribution. This caused variations in the glaze’s thickness and visual appearance, tarnishing the aesthetic appeal of their tiles.

The manufacturer opted for a ball mill grinder to finely grind the raw materials for the glaze, ensuring a uniform and controlled particle size. Additionally, they revamped their quality control processes by implementing automated inspection systems to identify any deviations in the glaze application.

The implementation of the ball mill grinder led to a consistent particle size distribution of the glaze material, resulting in uniform glaze thickness and enhanced visual appeal of the ceramic tiles. This revitalized the company’s market presence, as their products gained reputation for superior aesthetics and quality.

Our Projects

Copyright © ZENITH, All Right Reserved.