A ball mill is a crucial piece of equipment in the mining, metallurgy, and chemical industries. It is used to grind and blend materials for use in various processes like mineral dressing, pyrotechnics, ceramics, and selective laser sintering. The ball mill’s versatility and efficiency make it an essential tool for a wide range of industrial applications.

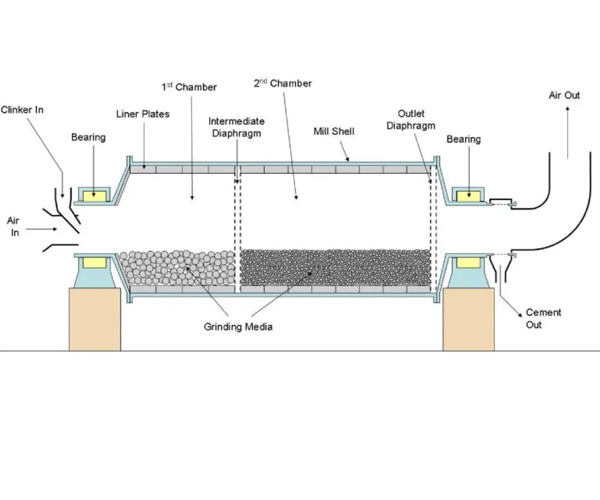

The shell of the ball mill is a cylindrical vessel, usually made of steel, that contains the grinding medium and the material to be processed. Its cylindrical shape allows for a more uniform and efficient grinding process, as the material and grinding medium are continuously cascading, lifting, and falling, imparting energy to the material. The shell is often lined with abrasion-resistant materials such as rubber or manganese steel to protect it from wear and extend its lifespan.

The grinding medium inside the ball mill is typically steel balls, ceramic balls, or sometimes, natural pebbles. The choice of grinding medium depends on the material being processed and the desired final product. Steel balls are commonly used in industrial ball mills due to their hardness and ability to efficiently grind materials. Ceramic balls are preferred for grinding delicate or abrasive materials as they offer excellent wear resistance and reduce the risk of contamination.

The drive system of a ball mill is responsible for turning the mill at a desired rotational speed. The power is transmitted to the mill through gears, pinions, or a direct central drive. The motor and gearbox arrangement provides the necessary torque to rotate the mill, ensuring efficient grinding. The drive system is also equipped with safety features to prevent overloading and protect the mill from damage.

The material to be ground is fed into the ball mill through an inlet chute. The design of the inlet chute is crucial to ensure a smooth flow of material into the mill while minimizing air ingress. Similarly, the outlet is designed to allow the finely ground material to exit the mill while preventing the grinding medium from leaving.

Ball mill liners play a significant role in protecting the mill’s shell from wear and tear caused by the grinding medium and the material being processed. Liners are made of rubber, metal, or composite materials and are designed to be replaceable. They can also influence the motion of the grinding media inside the mill, affecting the efficiency of the grinding process.

At the mill’s discharge end, a screen or grate is installed to retain the grinding media while allowing the finely ground material to pass through. The grate design can significantly impact the performance of the mill, influencing the size distribution of the final product.

A well-designed control system is essential for the efficient operation of the ball mill. It ensures optimal grinding performance, minimizes energy consumption, and protects the mill from overloading. The control system can be manual, semi-automatic, or fully automated, depending on the complexity and requirements of the milling process.

The smooth and reliable operation of a ball mill relies on high-quality bearings. These bearings support the rotating motion of the mill and reduce friction to prevent excessive wear. Proper lubrication and maintenance of the bearings are essential to extend their lifespan and avoid unplanned downtime.

The drive shaft transmits the rotational motion from the drive system to the mill shell. Support rollers are used to guide and support the mill’s rotation, ensuring smooth operation and preventing the shell from sagging or misaligning.

Safety is of utmost importance in any industrial setting, and ball mills are no exception. Several safety features are incorporated into the design to protect the operators and the equipment. Emergency stop buttons, protective enclosures, and proper lockout/tagout procedures are some of the safety measures commonly implemented.

In the realm of mineral processing, ball mills stand as a crucial tool in the mining industry. These mechanical devices have proven their worth time and again, being employed in various stages of the mining process, from raw ore extraction to the production of valuable minerals. The significance of ball mills in the mining sector cannot be understated, as they play a vital role in grinding, crushing, and refining ores, ultimately transforming them into valuable commodities that fuel economies around the world.

The mining industry primarily deals with the extraction of valuable minerals from the Earth’s crust. These minerals are often locked within ore deposits and must undergo several stages of processing to be extracted and refined for commercial use. The initial step in this process is the liberation of valuable minerals from the ore matrix. This liberation process is achieved through grinding, where the ore is broken down into smaller particles, allowing for the release of precious minerals.

Ball mills are renowned for their ability to effectively grind various types of ores, both soft and hard. Using the impact and attrition principles, ball mills crush and grind the ore into fine particles. The tumbling action of the steel balls within the mill further contributes to the liberation of minerals, separating them from the gangue (unwanted material) and making them available for subsequent processes.

Comminution, the process of reducing the size of ore particles, accounts for a significant portion of the total energy consumption in mining operations. As such, the efficiency of comminution has a direct impact on the overall energy consumption and operational costs in the mining industry. Ball mills have proven to be highly efficient in this regard, making them an indispensable tool for reducing particle size and energy consumption.

The design and engineering of modern ball mills have evolved significantly to improve energy efficiency. Various factors, such as ball size, rotational speed, and liner design, are carefully optimized to ensure the highest possible grinding efficiency. Additionally, the incorporation of advanced control systems and digital technologies allows for real-time monitoring and adjustments, further enhancing energy efficiency and reducing environmental impact.

Once the valuable minerals are liberated from the ore matrix through ball milling, the next step is their concentration. Concentration methods such as flotation, magnetic separation, and gravity separation are commonly employed to recover specific minerals of interest. Ball mills contribute to the concentration process by reducing the ore to a fine consistency, facilitating more effective mineral separation.

Flotation, for example, relies on the hydrophobicity of certain minerals. By grinding the ore to a finer size, ball mills increase the exposed surface area of minerals, enhancing their interaction with flotation reagents and increasing the overall flotation recovery.

One of the key reasons for the widespread use of ball mills in the mining industry is their versatility and adaptability to various ore types. Different mining operations deal with a wide range of ores, each presenting its unique challenges. Ball mills can handle diverse materials, from soft and friable ores to hard and abrasive ones, ensuring their relevance across different mining sites and scenarios.

Additionally, ball mills can be easily configured to meet specific requirements. This adaptability allows operators to optimize the milling process for the ore’s characteristics, thereby maximizing productivity and profitability.

Reducing Environmental Impact

In recent years, environmental consciousness has become a paramount concern in the mining industry. Companies are increasingly focusing on sustainable practices and minimizing their ecological footprint. Ball mills contribute to this endeavor by providing an energy-efficient grinding solution. The reduced energy consumption not only translates to cost savings but also helps in reducing greenhouse gas emissions and mitigating environmental impacts.

Cement is the most widely used construction material in the world, and its production is a complex and energy-intensive process. Among the various equipment utilized in cement manufacturing, ball mills play a crucial role. These mechanical devices are used to grind and blend raw materials to produce the fine powdered cement that we use in countless infrastructure projects and structures.

Before we explore the role of ball mills, it is essential to understand the cement production process. Cement is manufactured through a series of precise chemical reactions that involve the extraction and processing of raw materials such as limestone, clay, shale, sand, and iron ore. These raw materials are crushed and ground into a fine powder, commonly known as raw meal, which serves as the basis for the cement-making process.

Ball mills are cylindrical devices that rotate around a horizontal axis and are partially filled with the material to be ground, along with grinding media, such as steel balls or ceramic pebbles. The primary purpose of a ball mill is to reduce the size of raw materials and achieve a homogeneous mixture, essential for producing high-quality cement.

During the grinding process, the raw materials are progressively crushed by the impact and friction caused by the falling grinding media and the rotating mill shell. This action not only grinds the materials to the desired fineness but also ensures proper mixing and blending of the different components of the raw meal. The homogenized mixture is then ready for the next stage of the cement production process.

There are several types of ball mills commonly used in cement production:

These are the most common type of ball mills and are characterized by their simple design and ease of operation. They are suitable for grinding and blending various types of raw materials.

VRMs are a more modern and energy-efficient alternative to traditional ball mills. They utilize a rotating table and grinding rollers to crush and grind the raw materials. VRMs have a higher grinding efficiency and a lower power consumption compared to traditional ball mills, making them increasingly popular in the cement industry.

These ball mills are designed with a focus on energy efficiency and reducing carbon emissions. They often incorporate advanced control systems to optimize the grinding process and reduce energy consumption.

While ball mills are crucial for cement production, they are not without their challenges. Some of the common challenges faced in the operation of ball mills include:

Ball mills are notorious for their high energy consumption, which contributes to a significant portion of the overall production cost. Manufacturers are continuously seeking innovative ways to reduce energy consumption and improve overall efficiency.

The grinding media and the internal components of ball mills are subject to wear and tear due to the abrasive nature of the materials being processed. Regular maintenance and the use of wear-resistant materials are essential to prolong the mill’s lifespan.

Achieving consistent and high-quality cement is a constant challenge for cement producers. Variations in raw material properties, grinding efficiency, and process control can impact the cement’s performance and strength.

To address these challenges, cement manufacturers are investing in advanced technologies and process optimizations. They are using alternative fuels, such as biomass and waste materials, to reduce energy consumption and carbon emissions. Additionally, process control and automation systems are being employed to ensure consistent and efficient operations.

Zenith ball mill manufacturer has industrial ball mill and small ball mill for sale, power range 18.5-800KW. During the production process, the ball grinding machine may be called cement mill, limestone ball mill, sand mill, coal mill, pebble mill, rotary ball mill, wet grinding mill, etc.

Zenith ball mills are designed for high capacity long service and good quality.If you are interested in Zenith Ball Mill, you can contact us for more information about the selection, the price and other details of the equipment. The engineers will introduce the machines in detail for you.

Copyright © ZENITH, All Right Reserved.