With the rapid development of construction, mining, and infrastructure sectors in South Africa, the demand for stone crusher machines has been on the rise. These machines play a crucial role in converting raw materials such as rocks, minerals, and stones into smaller, more manageable sizes for various applications.

24 Online Service

The stone crusher industry plays a crucial role in the construction, mining, and infrastructure sectors of South Africa. These machines help convert raw materials such as rocks, minerals, and stones into smaller, more manageable sizes, making them suitable for various applications. With rapid urbanization, infrastructure development, and growth in the mining sector, the demand for stone crusher machines in South Africa has been on the rise.

The stone crusher industry in South Africa has a long history dating back to the early days of mining and construction. In the 19th century, manual labor was primarily used to crush and process raw materials. However, with the introduction of modern machinery and technology, the industry witnessed significant growth and development.

The demand for stone crusher machines increased due to the growth of the mining industry, especially during the gold and diamond rushes. In addition, the construction of infrastructure projects such as roads, bridges, and buildings also fueled the demand for these machines. Over the years, the industry has evolved, with the introduction of new types of stone crusher machines and advancements in technology, making the machines more efficient and environmentally friendly.

The stone crusher industry in South Africa faces several challenges that have the potential to impact its growth and development:

The extraction and processing of raw materials can have negative environmental impacts, including deforestation, habitat destruction, and pollution. The industry must implement sustainable practices and comply with environmental regulations to minimize its impact on the environment.

The stone crusher industry relies on the availability of raw materials to sustain its operations. Fluctuations in the supply of raw materials can impact the industry’s growth and profitability.

The industry requires skilled labor to operate and maintain stone crusher machines. However, South Africa faces a shortage of skilled labor, which can impact the industry’s growth and productivity.

Economic factors such as fluctuations in commodity prices, exchange rates, and inflation can impact the stone crusher industry. These factors can influence the demand for stone crusher machines and the overall profitability of the industry.

Stone crusher machines play a crucial role in the construction, mining, and infrastructure industries by converting raw materials into smaller, more manageable sizes. These machines are designed to process various types of rocks, minerals, and stones, and their efficiency largely depends on the raw materials being fed into the system.

Natural stones are one of the most common raw materials processed by stone crusher machines. These stones are extracted from quarries and can be categorized into several types, each with its unique properties and applications.

Hard and durable rock

Composed of quartz, feldspar, and mica

Used for construction, countertops, and monuments

Sedimentary rock composed mainly of calcite

Softer than granite but still strong

Used for cement production, road construction, and building materials

Composed of sand-sized mineral grains

Offers a variety of colors and textures

Used for building materials and decorative purposes

Metamorphic rock composed of recrystallized carbonate minerals

Known for its beauty and elegance

Used for sculptures, flooring, and countertops

Fine-grained, foliated metamorphic rock

Known for its durability and water resistance

Used for roofing, flooring, and landscaping

Gravel is a common raw material used in the construction industry for road building, concrete production, and landscaping. It is composed of small stones and rock fragments and can be produced naturally or by crushing larger rocks using stone crusher machines. Gravel is classified by size, ranging from fine to coarse, and can be made from various types of rocks, such as granite, limestone, and sandstone.

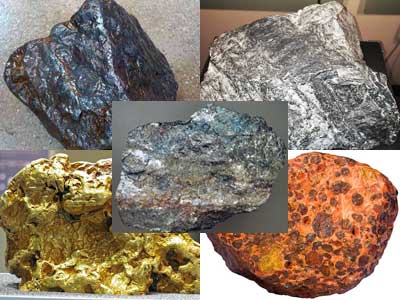

Stone crusher machines can also be used to process minerals and ores extracted from mines. These raw materials have various applications, including construction, manufacturing, and energy production.

Composed mainly of iron oxides

Used to produce steel and iron

Contains copper minerals

Used to produce electrical wiring, pipes, and other products

Contains gold particles

Used for jewelry, electronics, and investment purposes

Contains silver particles

Used for jewelry, electronics, and industrial applications

Composed primarily of aluminum hydroxide minerals

Used to produce aluminum and its alloys

In recent years, the use of recycled materials has become increasingly popular in the construction industry as a sustainable alternative to natural resources. Stone crusher machines can be used to process various types of recycled materials, such as concrete, asphalt, and brick.

Composed of cement, sand, and aggregate

Can be crushed and reused as a base for roads, driveways, and building foundations

Composed of bitumen, sand, and aggregate

Can be crushed and reused for road construction and maintenance

Made from clay or shale

Can be crushed and reused for landscaping or construction fill

Some industrial processes generate byproducts that can be used as raw materials for stone crusher machines. These materials can be crushed and repurposed for various applications, such as road construction, building materials, and landscaping.

Byproduct of steel production

Can be crushed and

Stone crusher machines have been an integral part of various industries, such as mining, construction, and infrastructure development. These machines are designed to crush and process different types of rocks, minerals, and stones into smaller, more manageable sizes. The type of stone crusher machine you choose should depend on your specific needs, such as the size and type of materials you need to crush, as well as the desired output size and production capacity.

Jaw crushers are one of the most common types of stone crusher machines. These machines work by using a compressive force to crush the materials between a fixed and a moving jaw. The moving jaw moves back and forth against the fixed jaw, causing the material to be crushed and broken down into smaller pieces. Jaw crushers are typically used in primary crushing applications and are ideal for processing medium to hard materials.

Simple design and operation

High crushing efficiency

Suitable for various materials, including hard rocks

Limited size reduction ratio

Possible uneven wear of jaw plates

Higher energy consumption compared to other crushers

Cone crushers are designed for secondary and tertiary crushing applications. These machines work by using a rotating cone, which crushes the material between its surface and the surrounding bowl liner. Cone crushers come in two main types: the standard type, which is used for coarse crushing, and the short head type, which is used for fine crushing.

High reduction ratio

Good product shape

Less wear and tear on components

Higher investment costs

Complex design and maintenance requirements

Not suitable for materials with high clay content

Impact crushers work by using a combination of impact and attrition to crush materials. These machines feature a rotor that spins at high speed, launching materials into the impact chamber, where they are crushed by the hammers and impact plates. Impact crushers are typically used for medium to soft materials and are known for their high reduction ratio and ability to produce cubic-shaped output.

High reduction ratio

Produces cubic-shaped particles

Suitable for a wide range of materials

Not suitable for very hard or abrasive materials

Higher wear and tear on components

Higher energy consumption compared to other crushers

Gyratory crushers are similar to cone crushers in their mode of operation, but they have a larger feed opening and a steeper crushing chamber. These machines are designed for primary crushing applications and are ideal for processing large, hard materials. Gyratory crushers have a central, vertical shaft that gyrates, crushing the material against the chamber walls.

High capacity and throughput

Suitable for large, hard materials

Efficient size reduction

Complex design and high investment costs

Difficult maintenance and repair

High energy consumption

The VSI6X Sand Making Machine is a cutting-edge technology that has revolutionized the way sand is produced for construction and other industries. With its advanced design and robust construction, the machine is able to produce high-quality sand that is ideal for use in a wide range of applications.

Simple design and low investment cost

Suitable for friable materials

Adjustable product size

Limited reduction ratio

Not suitable for very hard or abrasive materials

Wear on rollers may require frequent replacement

Mobile crushing plants are not a separate type of crusher but rather a combination of different crushers mounted on a mobile platform. These plants provide flexibility and mobility

Stone crusher machines are essential equipment in the construction, mining, and infrastructure industries. These machines help convert large rocks and stones into smaller, more manageable sizes, making them suitable for various applications. In South Africa, the demand for stone crusher machines has been on the rise, driven by rapid urbanization, infrastructure development, and mining sector growth.

The cost of a stone crusher machine in South Africa can be influenced by several factors, including:

Different types of stone crusher machines come with varying price tags. For example, jaw crushers and cone crushers are typically more expensive than impact crushers and roller crushers, owing to their complexity and higher production capacities.

The price of a stone crusher machine often depends on its production capacity. Machines with higher capacities tend to be more expensive as they can process more materials per hour.

Larger and more advanced stone crusher machines generally come with a higher price tag. Machines with additional features such as automation, remote control, or advanced hydraulic systems also tend to be more expensive.

The reputation and location of the manufacturer can also impact the cost of a stone crusher machine. Renowned international brands often command a higher price due to their reputation for quality and after-sales support. However, local manufacturers may offer more competitive prices with comparable quality.

Imported stone crusher machines may be subject to import duties and taxes, which can increase the overall cost. These additional costs should be considered when comparing prices between local and international suppliers.

The prices of stone crusher machines in South Africa can vary significantly based on the factors mentioned above. Here is a general price range for some common types of stone crusher machines:

Small and medium-sized jaw crushers: ZAR 250,000 – ZAR 1,000,000(Prices are for reference only and are not exact)

Large jaw crushers: ZAR 1,000,000 – ZAR 3,000,000(Prices are for reference only and are not exact)

Small and medium-sized cone crushers: ZAR 600,000 – ZAR 1,500,000(Prices are for reference only and are not exact)

Large cone crushers: ZAR 1,500,000 – ZAR 4,000,000(Prices are for reference only and are not exact)

Small and medium-sized impact crushers: ZAR 400,000 – ZAR 1,200,000(Prices are for reference only and are not exact)

Large impact crushers: ZAR 1,200,000 – ZAR 3,000,000(Prices are for reference only and are not exact)

Small and medium-sized roller crushers: ZAR 200,000 – ZAR 800,000(Prices are for reference only and are not exact)

Large roller crushers: ZAR 800,000 – ZAR 2,000,000(Prices are for reference only and are not exact)

Small and medium-sized mobile crushing plants: ZAR 1,500,000 – ZAR 4,000,000(Prices are for reference only and are not exact)

Large mobile crushing plants: ZAR 4,000,000 – ZAR 10,000,000(Prices are for reference only and are not exact)

Please note that these price ranges are approximate and can vary based on the factors mentioned earlier. It is essential to research and compare prices from different suppliers to ensure you are getting the best deal for your specific needs.

With the rapid development of construction, mining, and infrastructure sectors in South Africa, the demand for stone crusher machines has been on the rise. These machines play a crucial role in converting raw materials such as rocks, minerals, and stones into smaller, more manageable sizes for various applications. For those looking to purchase a stone crusher machine, it’s essential to understand the factors that influence the cost, performance, and longevity of the equipment.

When looking for a stone crusher machine for sale in South Africa, it’s essential to consider the various manufacturers and suppliers in the market. Some of the key players include:

Offer high-quality machines at competitive prices

Strong after-sales support and service

Renowned for advanced technology and quality

Higher price tag but often backed by extensive after-sales support

Provide access to stone crusher machines and spare parts

Offer essential services such as installation, maintenance, and repair

Before purchasing a stone crusher machine, consider the following factors to ensure you make the best decision for your specific needs:

Understand the type of material you need to crush

Choose a machine that is suitable for the hardness and size of the material

Determine the required output size

Select a machine that offers the desired size reduction and product shape

Assess your production capacity requirements

Choose a machine that can handle the required volume of material

Determine your budget for the stone crusher machine

Compare prices from different suppliers and manufacturers to find the best deal

Consider the availability of spare parts and maintenance services

Opt for a machine from a reputable manufacturer or supplier with strong after-sales support

When looking for a stone crusher machine for sale in South Africa, follow these tips to find the best deal:

Understand the different types of stone crusher machines available in the market

Identify the specific features and capacity requirements for your application

Obtain quotes from different manufacturers and suppliers

Compare prices, features, and after-sales support to find the best value

Our Projects

Copyright © ZENITH, All Right Reserved.